Powering Modern Tech: An Exploration of Electric Circuit Boards

An electric circuit board, commonly known as a PCB (printed circuit board), is the central foundation upon which electronic components are mounted and interconnected. Originating in the early 20th century, this technology transitioned from rudimentary wire connections to sophisticated multi-layered designs, serving as the silent enabler behind today’s electronic marvels.

Components and Structure of Electric Circuit Boards

Basic Components

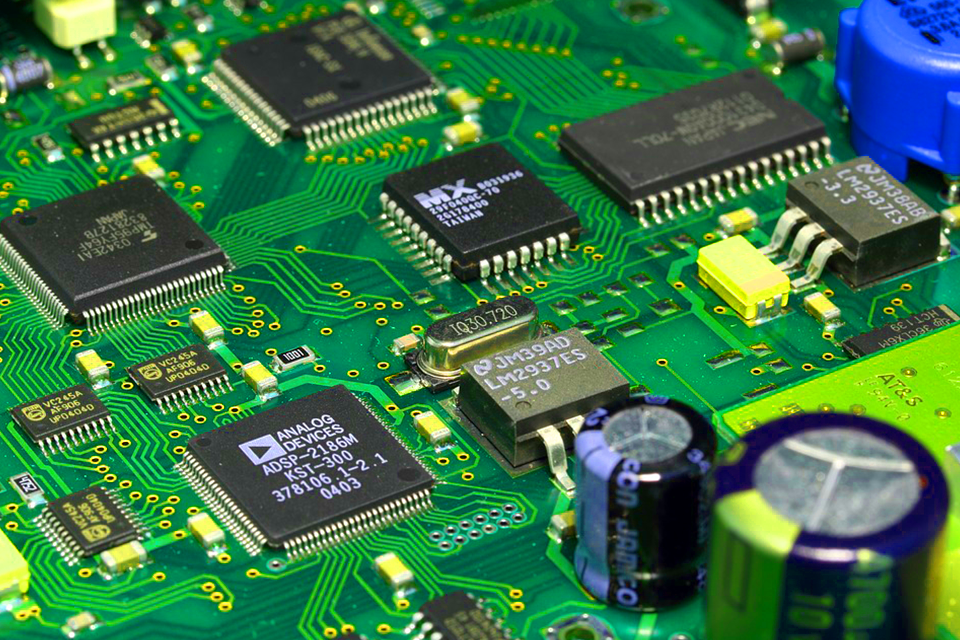

Central to an electric circuit board is a set of fundamental components, each with its unique function:

- Resistors: These components modulate the current flow, guaranteeing that various parts get the right power intensity.

- Capacitors: Operating as temporary energy reservoirs, capacitors manage and balance electrical charge, aiding in the consistent flow and regulation of voltage.

- Transistors: These are crucial for tasks like signal magnification and electronic switching, playing a significant role in diverse electronic operations, from sound amplification to data computations.

- ICs (Integrated Circuits): These are compact assemblies of myriad transistors and related components. They serve as the nerve centers for intricate operations in contemporary gadgets.

Layout and Design Considerations

Delving into the design and organization of a circuit board:

- Space Allocation: Efficient use of the board’s space is critical. Strategic positioning of elements guarantees operational effectiveness and optimal use of available space.

- Conductive Traces: The design of these copper routes, which guide the electricity, is essential to avoid signal disruption and to guarantee smooth power flow.

- Heat Regulation: Certain components emit heat. Strategically positioning them near cooling elements or vents is crucial to maintaining the board’s performance and durability.

- Arrangement of Components: The direction and positioning of components are pivotal, not only for their intended interaction but also to streamline the assembly process during production.

Varieties of Circuit Boards: Adapting to Modern Electronic Needs

The realm of electric circuit boards is diverse, with each type tailored for specific applications and functionalities:

- Single-sided Boards: These basic boards have components affixed on only one side, providing a straightforward design. Their simplicity and affordability make them a go-to for entry-level electronics.

- Double-sided Boards: These boards elevate the game by making use of both surfaces for components. Equipped with copper pathways on both sides, they accommodate more components, ideal for moderately complex electronic devices.

- Multi-layer Boards: Surpassing the dual-layer design, these boards integrate multiple layers of circuits stacked together. They’re indispensable in high-end electronics like PCs, maximizing functionality within a compact space.

- Rigid Boards: Sturdy and unyielding, these boards are commonplace in static devices such as desktop computers or TVs, where flexibility isn’t a requirement.

- Flexible Boards: Crafted from bendable materials, notably polyimide, these boards can contort, fitting into unconventional spaces or devices that require flexibility, like certain wearable tech.

- Rigid-flex Boards: A fusion of stability and adaptability, these boards incorporate both rigid and pliable sections. They’re paramount in specialized electronics, such as select medical instruments or aerospace tech, which demand a mix of firmness and flexibility.

The myriad of board types underscores the adaptability of circuit design, showcasing its evolution to meet the multifaceted demands of today’s tech landscape.

Journey of Circuit Board Creation: From Design to Final Product

The manufacturing of a circuit board is a meticulous process, ensuring each unit functions optimally:

Design to Prototyping

The journey commences with Computer-Aided Design (CAD) software, where electronic layouts are crafted digitally. Simulations are run to predict and rectify potential issues, resulting in a prototype that mirrors the final design.

Etching

Once the design is finalized, it’s time to imprint it on the board. A chemical solution is used to etch away unwanted copper, leaving behind the desired circuit pathways.

Laminating

Layers are added to the board for protection and insulation. This process involves applying a laminate, usually made of a material like epoxy resin, which also adds structural integrity.

Soldering

Components are then anchored to the board. This is achieved by melting solder – a fusible alloy – to attach components to their designated spots, ensuring a stable electrical connection.

Quality Checks and Testing

The penultimate step is critical. Each board undergoes rigorous inspections for defects or inconsistencies. Electrical tests ensure every connection is sound and the board functions as intended.

Applications and Use Cases of Circuit Boards: Powering Modern Life

Circuit boards are integral to a plethora of devices and systems we interact with daily:

Consumer Electronics

Nearly every electronic device in a household has a circuit board. Smartphones, with their compact yet powerful functionalities, rely on sophisticated multi-layer boards. Computers, both desktops and laptops, employ these boards to manage complex operations, ensuring seamless user experiences. Gadgets like tablets, smartwatches, and even modern refrigerators harness circuit boards to function.

Industrial Machinery and Automation

In industries, circuit boards are indispensable. They power automation systems, helping factories maintain precision and efficiency. Whether it’s controlling robotic arms in car manufacturing or regulating temperature in food processing plants, circuit boards ensure operational accuracy.

Healthcare Devices and Instrumentation

The medical field greatly benefits from circuit board-driven devices. Instruments like MRIs and X-rays rely on these boards for capturing and processing data. Additionally, wearable healthcare devices, such as heart rate monitors and insulin pumps, use circuit boards to provide real-time feedback and health metrics.

CONCLUSION

In the grand scheme of technological advancement, the electric circuit board stands as a silent, yet paramount pillar. These intricate pieces, often hidden within the casings of our favorite gadgets, are the unsung heroes powering our digital age. From the most rudimentary devices to the marvels of advanced tech, circuit boards bridge the gap between possibility and functionality. Their evolution and adaptation not only signify the leaps in electronic design but also forecast a future where their potential remains limitless. As we delve deeper into the era of technology, recognizing and understanding the role of these boards becomes ever more crucial. Truly, they are the heartbeat of modern tech.