Precision Aluminum Core PCB Manufacturing at Wenshu Factory: Unrivaled Quality and Expertise

Printed Circuit Boards (PCBs) serve as the heart of contemporary electronics, anchoring the majority of devices we rely on every day. They facilitate seamless communication between electronic components, guaranteeing consistent performance and dependability. Among the myriad of PCB variations, Aluminum Core PCBs are distinguished, especially for their superior thermal dispersion traits. Produced in dedicated facilities, these PCBs harness the natural heat-conducting property of aluminum, ensuring optimal operation even in high-heat scenarios. The benefits of Aluminum Core PCBs aren’t limited to just heat regulation; they also offer increased durability and lifespan, marking them as a top pick for diverse electronic applications.

The Wenshu Factory Difference

A Legacy of Excellence

Founded in 1994, Wenshu Factory has etched its name in the annals of PCB manufacturing. From its humble beginnings, we have grown exponentially, with its roots deeply embedded in a tradition of excellence and a commitment to the future of electronics. Every product that leaves the Wenshu facility carries the weight of its illustrious history and the promise of unmatched quality.

Mission & Vision

At the heart of Wenshu lies a mission to revolutionize electronic solutions by producing state-of-the-art PCBs. The factory envisions a world where electronics are not only efficient but also durable and sustainable. Our commitment is not just to meet industry standards but to set new ones, propelling the sector into a brighter, more innovative era.

Cutting-Edge Innovation

Technological prowess sets Wenshu apart. Investing heavily in R&D, the factory consistently pioneers advancements in PCB production. From introducing novel manufacturing techniques to integrating the latest in automation, Wenshu stands at the forefront of innovation. Our dedication to pushing boundaries ensures that we don’t just respond to industry demands – we anticipate and shape them.

Features of Aluminum Core PCBs

A Distinct Advantage

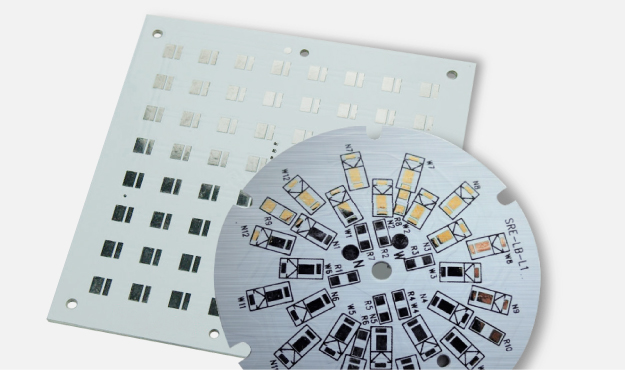

Aluminum Core PCBs aren’t your average circuit boards. Their unique construction, primarily centered around an aluminum core, provides them with properties that are often unmatched by traditional PCBs.

Multifaceted Benefits

- Heat Management: The standout advantage of Aluminum Core PCBs is their superior heat dissipation. The aluminum core acts as an effective heat spreader, reducing the risk of component overheating and enhancing the overall performance and reliability of electronic devices.

- Durability: Built to last, these PCBs offer greater mechanical strength, ensuring that they resist breakage or damage even in rigorous environments. The resilience offered by the aluminum base guarantees longevity, making it a cost-effective choice in the long run.

- Thermal Expansion Management: Aluminum Core PCBs effectively manage thermal expansion, ensuring minimal distortion even under fluctuating temperature conditions, a vital feature for maintaining component alignment and board functionality.

- Where They Excel: These PCBs are not just for any application; they truly shine in specific scenarios. Given their heat management capabilities, they are ideal for high-power LED applications, power converters, and automotive systems. Their durability makes them perfect for rugged environments, be it in industrial machinery or outdoor electronic setups. Furthermore, in high-frequency applications where minimal thermal expansion is crucial, Aluminum Core PCBs are the go-to choice.

Wenshu’s Manufacturing Process

Journey from Concept to Completion: Wenshu Factory prides itself on transforming raw materials into sophisticated Aluminum Core PCBs. The process, while intricate, is streamlined for optimal efficiency and precision.

Production Steps

- Material Preparation: The aluminum core is prepped, ensuring it’s free from contaminants.

- Circuitry Design: Advanced CAD tools draft the design, tailoring it to specific application needs.

- Layering: Insulating layers and copper foils are layered atop the aluminum base, creating the board’s foundational structure.

- Etching: Using precision machinery, unwanted copper is etched away, revealing the circuit design.

- Lamination: High-pressure laminates fortify the board, enhancing its robustness.

- Drilling and Plating: Holes are accurately drilled and then plated with copper, creating seamless connectivity for components.

- Solder Mask Application: To protect the board and ensure accuracy in soldering, a solder mask is applied.

- Final Inspection: Every board undergoes rigorous checks, ensuring they meet Wenshu’s gold standard.

Unwavering Commitment to Quality

- Assurance Measures: An in-depth testing phase, including electrical tests, visual inspections, and thermal cycling, ensures each board’s integrity.

- Control Protocols: By adhering to international quality standards and implementing regular audits, Wenshu maintains its legacy of producing faultless PCBs.

- Modern Tech at its Finest: What truly sets Wenshu’s process apart is the marriage of skilled craftsmanship and cutting-edge machinery. From state-of-the-art etching machines to advanced automation for quality checks, Wenshu employs the latest in technology, ensuring both speed and precision in manufacturing.

Environmental Considerations at Wenshu Factory

Eco-Conscious Manufacturing

Wenshu Factory recognizes the global call for sustainability and has integrated eco-friendly practices at the heart of its production. By optimizing energy use, minimizing wastage, and choosing sustainable raw materials, the factory ensures its manufacturing footprint treads lightly on the planet.

Recycle, Reuse, Reduce

- Material Recycling: Excess aluminum and other metals are routinely collected and recycled, ensuring minimal wastage and a reduction in raw material extraction.

- Waste Management: Wenshu implements a systematic approach to segregate and treat waste, ensuring hazardous by-products are handled safely and responsibly. Non-toxic waste, on the other hand, is efficiently repurposed or recycled.

- Water Conservation: Water used in the manufacturing process undergoes treatment and recycling, reducing overall consumption and ensuring cleaner discharges.

- Pledging a Greener Tomorrow: Beyond just immediate practices, Wenshu Factory is committed to long-term environmental goals. We invest in research to discover even greener production methods and collaborate with environmental bodies to stay updated on the best sustainable practices. Our pledge is clear: to not just produce superior Aluminum Core PCBs but to do so in a manner that prioritizes the planet.

CONCLUSION

Wenshu Factory is a testament to unparalleled excellence in Aluminum Core PCB production. Merging deep-rooted expertise, state-of-the-art technology, and a genuine dedication to environmental stewardship, we’ve established a benchmark in the realm of electronics. For those in pursuit of the finest in quality and performance, Wenshu Factory is the epitome of forward-thinking PCB craftsmanship, harmoniously balancing technological innovation and ecological mindfulness.