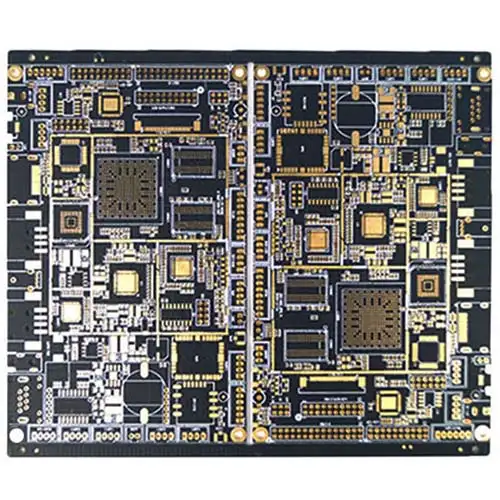

Cooker Hood Mother Board PCB Prototype

One of the key features of our prototype is its compact design, ensuring it fits within the limited space available in cooker hood enclosures. This compact form factor allows for easy integration and installation into different cooker hood models. This also ensures compatibility and flexibility.

| Layers | 2L |

| Size | 82.63*46.7mm |

| Plate Thickness | 1.6mm |

| Minimum aperture | 0.296mm |

| Line width/moment | 0.342*0.37mm |

| Surface treatment | gold plating process |

Prototype to Full Turn-Key Assembly

Through-Hole Lead-Free Wave Soldering

Best Price, Genuine Components

Quality Accreditation ISO9001

-

Description

-

Specification

Introducing our innovative prototype, the Cooker Hood Motherboard PCB Prototype – an expertly crafted circuit board meticulously engineered for the precise demands of cooker hood control systems. This groundbreaking design is the ultimate solution, ensuring impeccable control functionality while catering to the intricacies of cooker hood operation.

The Cooker Hood Motherboard PCB Prototype serves as the central nervous system, orchestrating a symphony of functions within cooker hoods. Integrating critical components such as microcontrollers, sensors, relays, switches, and connectors empowers comprehensive control capabilities.

Notably, our prototype boasts a space-efficient architecture, seamlessly slotting into the confined enclosures of cooker hoods. This deliberate compactness assures effortless assimilation across various cooker hood models, underscoring its versatility and broad-ranging compatibility.

Distinguishing itself through cutting-edge engineering, the prototype unveils a panorama of advanced control features, elevating the performance of cooker hoods. It harmonizes control like never before by elegantly choreographing multiple fan speeds, lighting nuances, and user-friendly interfaces like touch panels or intuitive push-button setups.

Moreover, the prototype’s sophistication shines with its integration of intelligent attributes. Equipped with temperature and airflow sensors, it optimizes ventilation efficacy, ensuring the efficient expulsion of smoke and odors.

Safety, an uncompromising pillar, remains at the core of our design philosophy. The prototype seamlessly aligns with rigorous safety standards, embedding indispensable safeguards such as fail-safe overcurrent and overheat protections. This fortified foundation guarantees not only the flawless operation of the cooker hood but also secures the longevity and reliability of all associated components.

We fervently recognize the individuality that defines each cooker hood system. Our Cooker Hood Motherboard PCB Prototype readily embraces tailoring and customization, seamlessly adapting to your requirements. This bespoke approach affords the integration of supplementary features and functionalities, harmonizing seamlessly with your unique cooker hood blueprint.

| Feature | Capability |

|---|---|

| Material | FR-4 Standard Tg 140°C, FR4-High Tg 170°C |

| Min. Track/Spacing | For External layers: 4oz Cu 10mil/13mil, 5oz Cu 12mil/15mil, 6oz Cu 15mil/15mil For Internal layers: 4oz Cu 8mil/8mil, 5oz Cu 10mil/10mil, 6oz Cu 12mil/12mil |

| Min. Hole Size | 0.15 ~ 0.3mm |

| Max Outer Layer Copper Weight (Finished) | 12oz |

| Max Inner Layer Copper Weight | 12oz |

| Board Thickness | 0.6-6mm |

| Surface Finishing | HASL lead-free, Immersion gold, OSP, Hard Gold, Immersion Silver, Enepig |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green |

| Silkscreen | White, Black |

| Via Process | Tenting Vias, Plugged Vias, Vias not covered |

| Testing | Fly Probe Testing (Free) and A.O.I. testing |

| Build time | 5-15 days |

| Lead time | 2-3 days |