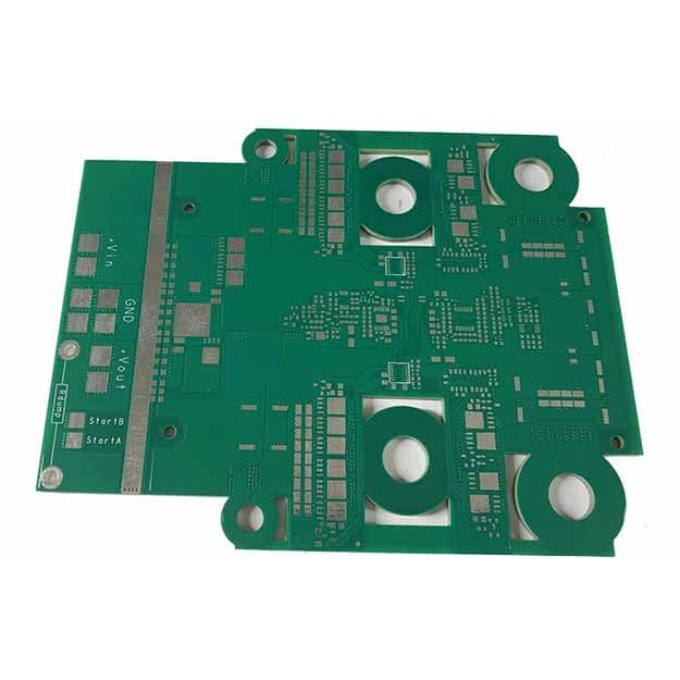

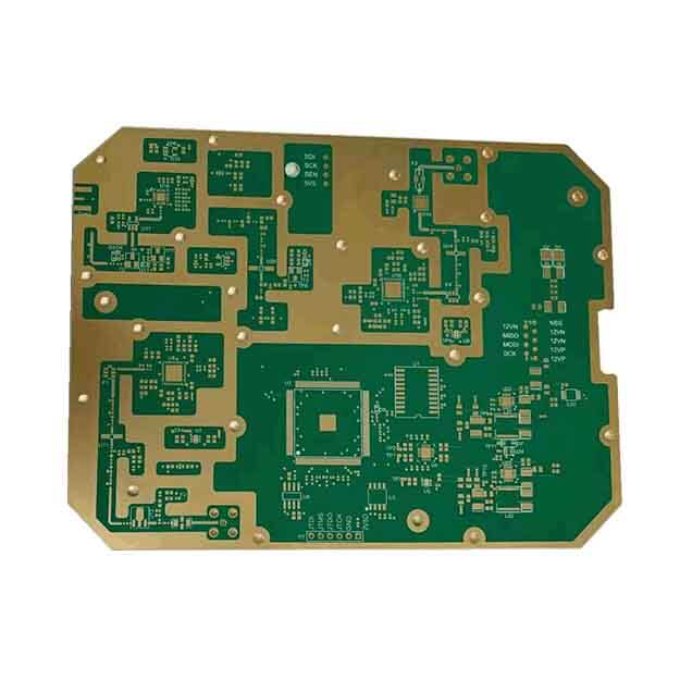

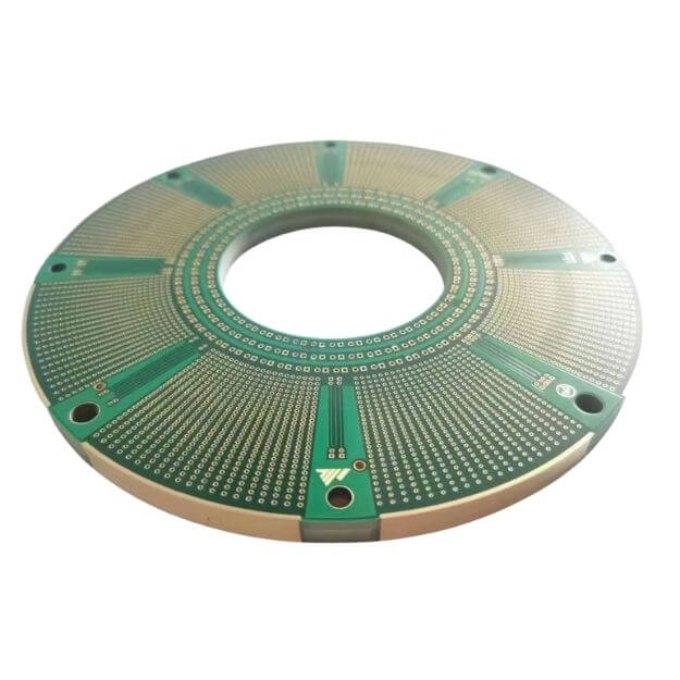

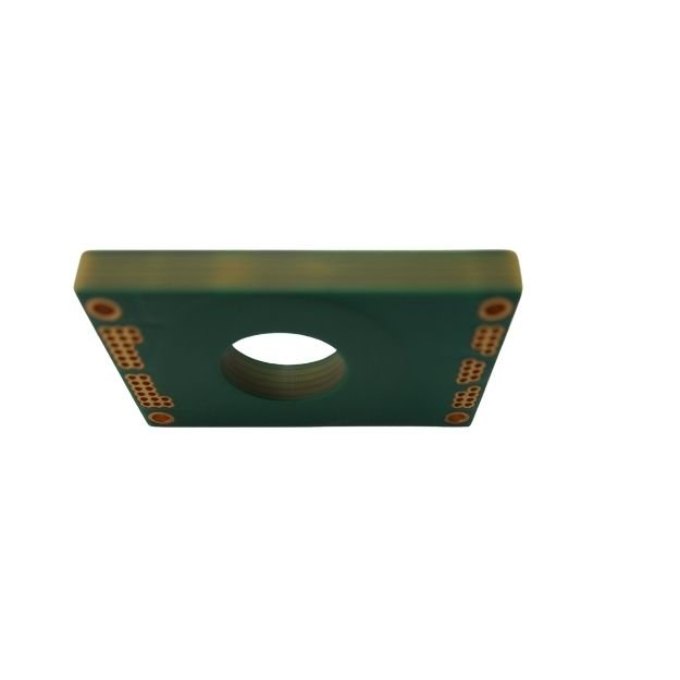

High Power PCB

Wenshu is a professional high-power PCB manufacturer in China. We can provide different types of high-power PCB for your project.

| Layer Count | 1-40layers |

| Board Thickness | 0.2-5.0mm |

| Copper Thickness | Min. 1/2 OZ, Max. 10 OZ |

| PTH Wall | 25um(1mil) |

| Maximum Board Size | 1100*500mm(43”*19”) |

| Min laser drilling size | 4mil |

Prototype to Full Turn-Key Assembly

Through-Hole Lead-Free Wave Soldering

Best Price, Genuine Components

Quality Accreditation ISO9001

-

Description

-

Specification

Introducing our High Power PCB, a remarkable solution designed to amplify the energy capabilities of your applications to new heights. Built to handle substantial power loads without compromise, this cutting-edge circuit board opens doors to a world of high-performance possibilities. Let’s delve into the exceptional features that define our High Power PCB:

- Unrivaled Power Performance: Our High Power PCB is engineered to manage substantial power levels with ease. Whether it’s industrial machinery, electric vehicles, renewable energy systems, or high-power electronics, our circuit board ensures efficient and reliable power distribution.

- Precision Craftsmanship for Safety: Safety takes precedence in our High Power PCB design. Expertly engineered with meticulous insulation, clearance considerations, and grounding techniques, our circuit board minimizes risks and guarantees secure operation even under high-power conditions.

- Versatility Across Industries: Embrace the versatility of our High Power PCB across diverse sectors. From powering advanced manufacturing equipment to driving sustainable energy solutions and propelling electric vehicles, our circuit board empowers innovation in various fields.

- Advanced Material Selection: At the core of our High Power PCB’s excellence lies the selection of superior materials. Our careful choice of substrates and dielectric materials ensures optimal heat dissipation, insulation, and energy efficiency.

- Thorough Testing and Quality Assurance: Every High Power PCB undergoes a battery of stringent tests to ensure its performance, resilience, and safety. From thermal cycling tests to high-power stress tests, we guarantee that each circuit board meets and exceeds industry standards.

- Tailored Manufacturing Excellence: Our manufacturing process employs state-of-the-art techniques and controlled environments to ensure the highest quality. Customization options are available to cater to your unique requirements, whether it’s size, power handling capacity, or layout design.

- Expert Consultation: Navigating the intricacies of high-power applications can be challenging. Our team of experienced engineers is on hand to provide guidance through every step of the process, ensuring that you make informed decisions aligned with your objectives.

- Reliable Partner for Advancements: In an era where high-power demands drive progress, our High Power PCB stands as a symbol of innovation, efficiency, and reliability. It serves as a catalyst for breakthroughs in your industry, equipped to handle the most demanding power-intensive tasks.

Elevate your applications, empower your inventions, and choose the High Power PCB that sets new benchmarks in energy performance. With our circuit board at your disposal, you’re equipped to lead the charge in the evolution of high-power technology. Propel your innovations forward, fuel your endeavors with unwavering power, and trust in a circuit board that’s built to excel under high-power demands.

| ltem | Capability |

|---|---|

| Layer Count | 1-40layers |

| Base Material | KB、Shengyi、ShengyiSF305、FR408、FR408HR、IS410、FR406、GETEK、370HR、IT180A、Rogers4350、Rogers4000、PTFE Laminates(Rogers series、Taconic series、Arlon series、Nelco series)、Rogers/Taconic/Arlon/Nelco laminate with FR-4 material (including partial Ro4350B hybrid laminating with FR-4) |

| Board Type | Backplane、HDI、High multi-layer blind&buried PCB、Embedded Capacitance、Embedded resistance board 、Heavy copper power PCB、Backdrill, PCB Gold Finger |

| Board Thickness | 0.2-5.0mm |

| Copper Thickness | Min. 1/2 OZ, Max. 10 OZ |

| PTH Wall | 25um(1mil) |

| Maximum Board Size | 1100*500mm(43”*19”) |

| Min laser drilling size | 4mil |

| Min.spacing/Tracing | 2.7mil/2.7mil |

| Solder Mask | Green, Black, Blue, Red, White, Yellow, Purple matte/glossy |

| Surface Treatment | Flash gold(electroplated gold)、ENIG、Hard gold、Flash gold、HASL Lead-free 、OSP、ENEPIG、Soft gold、Immersion silver、Immersion Tin、ENIG+OSP, ENIG+Gold finger, Flash gold(electroplated gold)+Gold finger(50u”), Immersion silver+Gold finger, Immersion Tin+Gold finger |

| Min. Annular Ring | 3mil |

| Aspect ratio | 10:1(HASL Lead-free 、HASL Lead、ENIG、Immersion Tin、Immersion silver、ENEPIG);8:1(OSP) |

| Impedance control | ±5ohm(<50ohm), ±10%(≥50ohm) |

| Other Techniques | Blind/Buried Via, Gold Fingers, Press Fit, Via in Pad, Electrical Test |