Exploring the World of Custom Circuit Board Printing: A Revolutionary Technology for the Electronics Industry

Electronics Revolutionizing: Custom Circuit Board Printing Comes

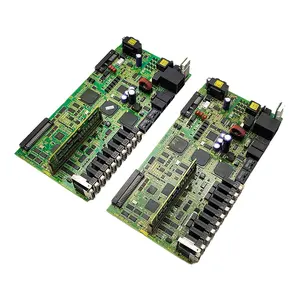

- Custom circuit board printing is a ground-breaking breakthrough grabbing the attention of engineers, designers, and manufacturers alike in the fast-paced world of technology, where innovations appear overnight. This innovative technology has the potential to completely alter the way electronics are made, opening up new opportunities for innovation, efficiency, and design. Circuit board construction has kept to traditional approaches for many years, requiring complex procedures like etching, drilling, and soldering.

- It is fundamentally an additive manufacturing process that combines the building of circuits with 3D printing concepts. This fusion of disciplines makes it possible to build circuits layer by layer on a substrate, ushering in a new era of flexibility and creative freedom. This invention has wide-ranging implications. The limitations of manufacturing methods have traditionally placed limitations on the design process for electrical devices. With the help of circuit board printing, these limitations are destroyed, enabling engineers to create elaborate, unusual designs that were previously unthinkable. The options are as endless as the imagination, ranging from elaborately designed wearables that conform to the body to little IoT gadgets that blend perfectly into any surroundings.

Unlocking Innovation and Efficiency in Electronics Manufacturing:

The industry has changed dramatically due to technology advancements like custom circuit board printing. Efficiency and innovation are critical in the fast-paced world of electronics production. This innovative technique of making circuit boards has several advantages over conventional manufacturing processes, opening the door for previously unheard-of innovation and productivity in the industry. The creation of custom circuit boards, commonly referred to as additive manufacturing or electronic 3D printing, is changing how electronics are made. They create the circuitry layer by layer using specialized inks impregnated with conductive elements instead of typical processes that entail etching copper layers onto substrates. This not only makes production easier but it also gives designers more options.

- The flexibility it offers in design and prototyping is one of the main benefits of printing bespoke circuit boards. Complex circuit layouts are frequently created using lengthy, labour-intensive processes in traditional manufacturing techniques. With circuit board printing, designers can quickly transform their concepts into working prototypes, accelerating time to market. Engineers can test and improve concepts without conventional production’s limitations because of prototyping’s speed and flexibility.

- Custom-printed circuit boards have more features than regular rigid circuit boards. This technology opens up new possibilities for product design by allowing the fabrication of flexible and even three-dimensional electronics. The adaptability of bespoke circuit board printing opens up creative uses across several sectors, from wearable electronics that fit the body’s curves to sensors that can be incorporated into irregularly shaped products.

- Custom circuit board printing has many benefits, but it’s also crucial to recognize its existing limits. Since the technology is still developing, issues like maintaining uniform conductivity and streamlining the printing procedure must be resolved. Nevertheless, the limits of what is possible are pushed through continual research and development.

Electronics Revolutionized by Custom Circuit Board Printing:

These printing techniques create waves and change how we think about circuit boards in the ever-evolving electronics sector. This ground-breaking development has the potential to fundamentally alter how electronic gadgets are created, used, and function, bringing up new opportunities for creativity and productivity. Etching, drilling, and soldering are a few of the complex and time-consuming procedures used in traditional circuit board fabrication. The intricacy of the designs, the speed of manufacturing, and the cost-effectiveness of these approaches are frequently constrained. The circuit board printing is, however, altering this story. Custom circuit board printing is fundamentally an additive manufacturing process that builds sophisticated circuitry layer by layer. Many of the limitations of traditional production are removed by this method. Here are some ways that technology is changing the electronics sector:

- Design Flexibility:

Engineers and designers may escape traditional production limitations using bespoke circuit board printing. Complex and unusual forms that were formerly thought to be unworkable can now be easily included in the design of electrical gadgets. More ergonomically sound, functional, and visually beautiful goods will result.

- Rapid prototyping:

Creating moulds and other tools is necessary for traditional circuit board manufacture, which can drastically slow down the prototyping stage. This procedure is sped up by custom circuit board printing, which enables quick iterations and rapid prototyping. This flexibility is essential for businesses looking to launch goods more quickly.

- Less Material Waste:

The requirement for cutting and etching during traditional production processes frequently results in material waste. On the other side, printing custom circuit boards is a minimally wasteful additive procedure. This environmentally friendly strategy fits with the increasing focus on sustainability across businesses.

- Miniaturization:

As electronic devices continue to get smaller, there is a growing need for more compact and powerful circuitry. With the ability to precisely manage trace widths and component placement through custom circuit board printing, it is possible to design tightly packed circuits perfect for downsizing.

- Individualization and Customization:

The capacity to build specialized circuit boards provides opportunities for specialized remedies. Whether it’s a consumer item with a customized look or medical equipment with specialized sensors, manufacturers may design goods that cater to individual demands.

- Accessibility:

The printing of custom circuit boards democratizes the electronics industry. Now, smaller businesses and even lone inventors may realize their ideas without the need for significant resources or collaborations with major manufacturers.

What Custom Circuit Board Printing in Electronics Can Do for You?

Innovation is the power that propels the future in the exciting world of electronics. This printing stands out as a game-changer redefining how we design, produce, and use electrical products among the recent technical wonders that have captured the spotlight. This innovative strategy provides many advantages to transform the sector and open up previously unimaginable opportunities.

- Design Freedom:

Custom-printed circuit boards free designers from the limitations of conventional production processes. They are given the ability to innovate and make complex forms that differ from the usual rectangular boards. With this newly discovered design freedom, it is now possible to utilize space more effectively, create more ergonomically sound products, and incorporate electronics into various form factors.

- Rapid prototyping and iteration:

The day of labour-intensive prototype procedures, including the development of moulds and tooling, is long past. The design cycle becomes more agile with the help of custom circuit board printing, allowing for speedier iterations and rapid prototyping. Engineers can now quickly transition from an idea to a workable prototype, experiment with various designs, and make changes on the fly, shortening the market time.

- High-Density Circuits:

The need for more potent yet smaller electronic products is always expanding. With the help of custom circuit board printing, it is possible to make tightly packed circuits with exact trace widths, enabling downsizing without sacrificing performance. This is essential in fields where space is at a premium, such as wearables, medical devices, and IoT.

- Complex Multi-Layer Designs Made Simple:

Creating multi-layer circuit boards using standard techniques necessitates delicate layer alignment and challenging assembly procedures. This is made easier by circuit board printing, which enables the production of intricate multi-layer boards using a single additive process, lowering the chance of mistakes and increasing overall dependability.

- Customization and Tailored Solutions:

Because every application has different demands, manufacturers can now better meet those needs using circuit board printing. This technology provides customized solutions that answer the numerous demands of many sectors, whether through the integration of special sensors, connections, or unique form factors.

NewHonest: Your Trusted Circuit Board Printing Manufacturer:

Innovation is the engine of advancement in the quick-moving world of technology. Here comes NewHonest, a ground-breaking maker of custom circuit boards that is revolutionizing how we view electronics design and production. With a dedication to expanding the realm of the possible, NewHonest is your partner in creating cutting-edge electrical devices. Your vision may become a reality because to NewHonest. To fully grasp your specific needs and realize your visions, our team of skilled engineers and designers works together with you. At NewHonest, we are aware that conventional manufacturing techniques can have constraints that impede innovation and slow down production. To overcome these limitations, we have tapped into the potential of bespoke circuit board printing, a cutting-edge technology.

Conclusion:

The creation of custom circuit board printing has, in turn, caused a paradigm change in the electronics industry. Its advantages, which include customization, decreased waste, and quick prototyping, are expected to alter sectors and usher in a new era of innovation. We may look forward to a time when bespoke circuit board printing will enable electronics to be moulded by its endless potential rather than being constrained by the limits of the present. NewHonest defines and lays out clear objectives and benchmarks for environmental controls, and we continually assess the outcomes of environmental actions to make further advancements. With the cooperation of every worker in the production, we always manage environmental protection operations.