A comprehensive guide on pcbway pcb

What is exactly pcbway pcb for?

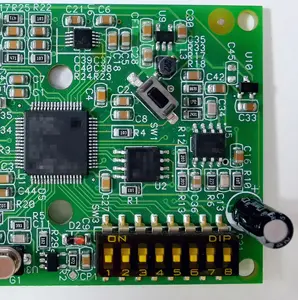

Manufacturing printed circuit boards or pcbway pcb is essential to the electronics sector. As technology develops, the need for top-notch PCBs that provide outstanding performance has substantially expanded. In addition to having a user-friendly web platform and affordable prices, we are renowned for our versatility in handling several facets of PCB manufacture, from design and fabrication through assembly and testing. We provide PCB manufacturing services to a large number of professionals, businesses, and amateurs for a variety of electronic applications.

PCB is an abbreviation for “Printed Circuit Board.” It is a crucial part of most electronic gadgets and is a platform for attaching and sustaining different electrical components. PCBs are used to mechanically support and electrically link electronic components using conductive paths, traces, and signal lines that have been etched into a non-conductive substrate material.

A Closer Look at a PCB’s Structure and Its Anatomy

PCBs, or printed circuit boards, are the heroes of today’s electronics industry. From cell phones to microwaves, these tiny, apparently inconspicuous boards are crucial components in almost every electronic gadget we use today. In this thorough study, we’ll examine PCB construction’s essential elements and importance in electronics.

A description of PCBs

A printed circuit board, or PCB for short, is a crucial part of the manufacture of electronics. Its main objective is to give different electronic components a stable basis for connection and support, thereby converting a collection of unrelated pieces into an electronic system that works.

Key Elements of a Base Material or PCB Substrate: The Starting Point

The substrate, also known as the foundation material or PCB core, is the essential component of any PCB. This substrate normally consists of epoxy resin bonded with fiberglass, giving the board longevity and mechanical strength. To etch the electrical circuit, it acts as a canvas.

The Conductor Copper Foil

The substrate is coated with thin copper foil sheets that are connected to create the conductive channels required for electrical connections. Copper is the ideal material for this because of its outstanding electrical conductivity. Depending on the particular needs of the PCB, there might be variations in the thickness and distribution of the copper layers.

The PCB’s Layers

PCBs are not only straightforward, single-layered boards; they frequently include numerous layers, each with a specific function. A crucial component of PCB design and assembly is the layering configuration.

- Routing the Connections at the Signal Layers

Copper traces in charge of transporting electrical signals are present in signal layers. On the PCB, these traces link different components in complex patterns. A PCB may have one or more signal layers, depending on the circuit’s complexity.

- Ensure Stability with Power and Ground Planes

Voltage and power signals are carried by certain layers on the PCB called power planes. Ground planes are used for grounding, as the name implies. These layers support a steady and low-resistance electrical channel for the circuit, minimizing electromagnetic interference and supplying even power distribution.

- Insulation and Protection from Solder Mask

The copper traces are shielded by the solder mask, which also serves to forbid accidental electrical connections. To ensure that only the required regions are joined during the soldering process, it is often constructed of a polymer resistant to high temperatures. Additionally, the solder mask offers insulation and defense against the elements, such as moisture and dust.

- Component labeling using silkscreen

The silkscreen layer’s markings, labels, and component outlines make the PCB easier to assemble and maintain. The layer shows logos, component reference designators, and other helpful data, making it simpler for engineers and technicians to deal with the board.

A PCB with electronic components

PCBs are more than simply layers of materials; they are the platform on which electronic parts are assembled to create a working system. These elements consist of:

- Integrated Circuits (ICs): The Operation’s Minds

Integrated circuits power electronic gadgets, sometimes referred to as microchips or ICs. They could have memory chips, microprocessors, and several other specialized features. With solder connections or special packaging, ICs are installed onto the PCB.

- The Silent Supporters are passive components.

Passive elements such as resistors, capacitors, and inductors are vital for regulating and modifying electrical impulses. They are frequently modest and undetectable yet are crucial for influencing the circuit’s behavior.

- Amplifiers for the signals are active components.

Transistors and diodes are active components that actively regulate and enhance electrical impulses. These parts are in charge of switching, amplification, and signal control.

- Gaps-Bridging Connectors

Physical connections between the PCB and other PCBs or external devices are made via connectors and sockets. They can be found in several configurations, such as pin headers, USB ports, and audio jacks.

Demystifying the Marvels of pcbway pcb: A Closer Look at Printed Circuit Boards

The foundation of contemporary electronics, pcbway pcb, is essential to many gadgets we use every day. They offer a sturdy foundation for joining electronic parts, allowing for the smooth exchange of electrical impulses. We shall examine the advantages of employing PCBs in this article, including their dependability, effectiveness, and role in promoting technological progress.

- Consistency and Dependability

The unrivaled dependability of PCBs is one of its main advantages. In contrast to conventional point-to-point wire, PCBs enable reliable and long-lasting electrical connections, where connections can be vulnerable to damage. The board’s etched copper traces offer a safe route for electrical signals, reducing the possibility of loose connections, shorts, or other electrical problems.

- Small Design

Compact electrical devices may be made thanks to PCBs. PCBs provide engineers with an organized platform for component placement and connections, allowing them to create effective and compact circuits. This is especially helpful when creating portable products like smartphones, laptops, and wearables because size and weight reduction are critical considerations.

- Performance Improvement

The electrical properties of the circuit, such as impedance and capacitance, are uniform and predictable thanks to the regulated manufacturing process of PCBs. Improved signal integrity and less electromagnetic interference (EMI) are benefits of this. PCBs are, therefore, perfect for high-frequency and high-speed applications, such as cutting-edge microprocessors and communication hardware.

PCBs may be produced in large quantities at a reasonable price. A finished PCB design makes fabricating it in large quantities reasonably affordable. The consumer electronics market is significantly impacted by this cost-effectiveness, which lowers the price of items like smartphones and tablets for various users.

- Assembly is simple

Component assembly into a PCB is a streamlined and effective procedure. The two main techniques for attaching components are through-hole technology (THT) and surface-mount technology (SMT). Both approaches enable exact component insertion and automated soldering, resulting in dependable and premium assembly.

- Scalability

Different circuit complexity may be easily accommodated by scaling up or down pcbway pcb designs. PCBs may be customized to match individual requirements, allowing you flexibility in design and manufacture whether you’re designing a basic LED torch or an intricate aircraft system.

- Error Rate Drop

Manufacturing procedures and PCB design software have improved to reduce human error. Modern CAD technologies assist engineers in visualizing and validating their ideas, which lowers the possibility of design faults. Automated assembly procedures also significantly lower the chance of mistakes during component insertion and soldering.

- Customization

To satisfy the particular requirements of varied applications, PCBs provide a high level of customization. Engineers can create PCBs with specified layouts, trace thicknesses, and layer counts to maximize performance. This customization enables the development of specialized PCBs for sectors such as the automotive and medical device industries.

- Simple upkeep and repairs

PCBs are often simple to diagnose and fix if a problem or component fails. In many cases, technicians may find damaged components, desoldered, and replaced with new ones without needing a brand-new PCB. This simplicity of maintenance is especially useful in sectors like manufacturing and telecoms, where downtime is expensive.

- Environmental Advantages

PCBs support long-term environmental viability. Because of their small size, electronic gadgets are more portable, which results in less material usage. The recyclability of PCB components like copper and fiberglass encourages safe disposal methods.

- Progress in Innovation and Technology

The use of PCBs has been crucial in promoting technological advancement. PCBs have made it possible to develop increasingly complex and potent electronic devices, from the invention of the transistor to the development of microprocessors and beyond. They still serve as a pillar for technological development in industries like artificial intelligence, renewable energy, and space travel.

Conclusion:

Pcbway pcb is a crucial part of every electronic gadget we use today. PCBs are essential for connecting and powering numerous electronic components in various devices, including mobile phones, computers, televisions, and medical equipment. Knowing the fundamentals of PCBs is crucial for those interested in electronics and passionate about learning how gadgets operate. To achieve additional breakthroughs, NewHonest defines and sets out certain standards and targets for environmental management. We also continuously evaluate the results of our environmental initiatives. We always oversee environmental protection procedures with the help of each industrial worker.