A Comparative Analysis of NewHonest PCB Printing Company Performance in the Industry

The Evolution of PCB printing: From prototype to perfection

Printed circuit boards, or PCBs, are the heroes in contemporary electronics. They serve as the foundation for many everyday items, including cell phones and medical technology. PCB printing has developed from straightforward prototypes to complex designs due to consumer demand for more functionality, miniaturization, and efficiency. The voyage of PCB printing is explored in this essay, focusing on the crucial steps that took us from crude prototypes to the pinnacle of perfection. NewHonest, pcb printing company, produced pcb.

Early Period:

The Development of prototyping PCBs has a long history that began in the 20th century when the idea of linking electrical components became popular. Point-to-point wiring, which required a lot of manual labour and was prone to mistakes, was initially used to assemble circuits. Even though connection was enhanced in the 1940s by methods like wire wrapping, the first real PCB prototypes appeared in the 1950s. These early boards, which substantially improved efficiency, employed adhesive-backed copper sheets and different insulating layers.

- Photoetching and perforated boards’ development

With the invention of photo etching, the 1960s witnessed a dramatic paradigm shift. Using a photoresist layer, this ground-breaking technology allowed for constructing more complex circuit designs. Through the use of a mask, the photoresist was exposed to light. Extra copper was then removed using chemical etching. Perforated boards with pre-drilled holes have also grown popular because they make soldering and component insertion easier.

- PCBs ranging from single to double-sided

Double-sided PCBs replaced single-sided ones in the 1970s, allowing for more design flexibility and smaller boards. The necessity to fit more complicated circuits in smaller devices sparked the breakthrough. Improved circuit density was made possible by including many layers of copper traces coupled via plated-through holes on double-sided PCBs.

- PCBs with several layers: Exploding Complexity

The need for more functionality drove PCBs to unprecedented heights as technology advanced. Multilayer PCBs first appeared in the 1980s, allowing for even more circuit complexity in a smaller footprint. These circuit boards had numerous copper traces joined by vias, separated by insulating layers. High-performance electronics are now possible because of this innovation.

- SMT or surface mount technology

Surface Mount Technology (SMT) emerged, revolutionising how components were put on PCBs in the 1990s. Unlike conventional through-hole components, SMT components might be mounted directly onto the board’s surface. This resulted in increased component density, lower manufacturing costs, and enhanced signal integrity.

- High-Density Interconnect (HDI) PCBs and miniaturization

The quest for miniaturization and high-density interconnects has defined the 21st century. From wearables to Internet of Things gadgets, miniaturization has made it possible to create smaller and more portable electronics. Using cutting-edge materials and methodologies, High-Density Interconnect (HDI) PCBs go one step further and cram more components and traces into a smaller area. This is accomplished by using micro vias, blind vias, and buried vias, which improve signal integrity and lower electrical noise.

- 3D printing and advanced materials

Today, various cutting-edge materials, including flexible substrates, PCBs made of ceramic, and even 3D-printed PCBs, are used to make PCBs. Flexible PCBs are perfect for wearable technology and other atypical form factors because they can bend and conform to irregular forms. By utilizing additive manufacturing, 3D-printed PCBs make building intricate, three-dimensional circuitry possible.

NewHonest: The top-notch PCB printing company that delivers quality and reliability

Printed Circuit Boards (PCBs) are the innovation’s fulcrum in the fast-paced field of electronics. These complex circuit systems underpin modern technology, from cell phones to medical equipment. The importance of PCB printing firms develops since there is a rising need for more compact and efficient electronics. Among the top contenders in this market, NewHonest, a pcb printing company, stands out as a steadfast symbol of excellent quality and dependability. In this post, we explore what makes NewHonest unique regarding PCB printing.

- A Tradition of Excellence

Since our founding over 20 years ago, NewHonest has established a strong name in the PCB printing sector. Our business has continuously surpassed expectations by providing clients in various industries with high-quality solutions because of a deeply ingrained dedication to excellence. Our experience spans various sectors, from aerospace to automotive, gaining the respect of established businesses and cutting-edge startups.

- Quality as the Cornerstone

A steadfast commitment to quality is at the core of NewHonest success. We put each PCB they make through arduous testing and inspection procedures to ensure the finished product satisfies the highest industry requirements. Every step of the production process, from design validation through manufacturing and final assembly, is covered by NewHonest quality control methods. Due to our rigorous attention to detail, even the most demanding applications will not encounter any issues with PCBs.

- Reliability that Counts

At NewHonest, pcb printing company, reliability is a promise that is kept with each project that is taken on. Electronics is a field that moves quickly, and downtime and malfunctions can result in significant losses. Understanding this important factor, we go above and beyond to provide PCBs that are not only of the highest quality but also very dependable. Numerous clients that depend on NewHonest PCBs for mission-critical operations attest to their success.

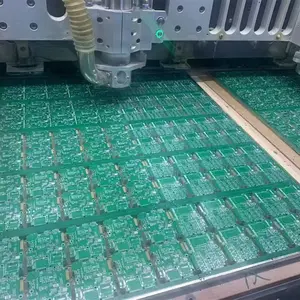

- Contemporary Facilities

The proper tools are necessary to succeed, and we make no compromises regarding our facilities. Our production facilities, outfitted with cutting-edge gear and technology, are evidence of our dedication to innovation. The facilities at NewHonest are a testament to our commitment to keeping at the cutting edge of PCB printing technology, from sophisticated automation systems that assure precision to environmentally controlled rooms that optimize manufacturing conditions.

Why choose NewHonest?

We, pcb printing company, serve as cornerstones of excellence and dependability in a world where PCB printing is crucial to technological development. NewHonest has shaped the PCB printing industry with a history of quality, a passion for innovation, and a constant focus on our customers. We will stay on top of technological developments and new difficulties by providing excellent PCB solutions that set the bar for the sector.

- Expert Engineers’ Team

A group of knowledgeable engineers familiar with the complexities of design, manufacturing, and assembly stand behind every successful PCB. A team of professionals with years of expertise makes up NewHonest. These engineers work directly with customers, providing insightful advice to improve designs for usefulness and manufacturability. This teamwork makes the production process go more smoothly and improves the final product as a whole.

- Flexibility and Personalization

Since no two projects are similar, NewHonest recognizes the value of customizing its offerings to satisfy various needs. We specialize in providing tailored solutions, whether a large multilayer PCB for an advanced medical device or a little board for an IoT device. Their ability to adapt to various design requirements distinguishes them as a partner who genuinely comprehends the various objectives of our clients.

- Responsibility for the environment

We take our obligation seriously at a time when environmental awareness is crucial. We follow strict environmental regulations and, if feasible, use eco-friendly products and techniques. By adopting sustainable practices, we show our dedication to moral business practices and helping to create a greener future.

- Customer-Centered Approach

The client-centric approach of NewHonest is what sets them apart. We go above and beyond to ensure customer happiness since they understand how important our client’s businesses are to succeed. We are renowned for our open communication, rapid replies, and readiness to handle any issues that may emerge from the initial consultation through post-production assistance.

How pcb printing revolutionizing is the manufacturing process?

The manufacturing process has undergone a radical transition thanks to PCB printing, significantly altering how electrical products are created, manufactured, and assembled. The complex process of designing circuits has been reduced, making it quicker, more effective, and astonishingly exact. Automated procedures that create elaborate and tightly packed circuits have replaced conventional techniques of hand-wiring and point-to-point connections, allowing for the development of smaller, lighter, and more potent devices. Furthermore, PCB printing makes it possible to incorporate cutting-edge elements like multilayer designs, high-density interconnects, and surface mount technologies, all of which improve the overall functioning of electronic devices. This transformation has shortened production lead times and improved industry-wide uniformity and quality, ushering in a new era of electronics manufacturing that places a premium on effectiveness, precision, and creativity.

Conclusion:

The modest PCB is where it all begins in the world of electronics, which is full of limitless opportunities and inventions. The creation of electronic devices now requires printed circuit boards (PCBs), and improvements in PCB printing technology have completely changed how manufacturing is done. By resolving the problems with conventional production methods, we have positioned ourselves as a catalyst for technological innovation. NewHonest, the pcb printing company, lets organisations swiftly transform their ideas into reality by emphasizing speedy prototyping, cutting-edge technology, and seamless supply chain management. With the development of technology, the future is made possible by our commitment to quick turnaround times.