Ensuring Safety: The Importance of Safe PCB Design

The introduction of safe pcb:

A safe pcb, also known as a printed circuit board, is a circuit board that has been carefully constructed to assure dependability, reduce hazards, and follow safety regulations while it is in use. Electronic gadgets are supported by PCBs, which direct the movement of electrical impulses between components. A PCB design reduces the possibility of failures that cause financial loss or safety risks while improving electronic equipment’s performance and durability. Engineers and designers must carefully consider each of these factors to create PCBs that adhere to strict safety requirements. This will guarantee smooth functioning and end-user peace of mind. It is crucial to ensure their safety to avoid malfunctions, damage, or even risks.

Safety First: The Value of Safe PCB Design

One thing never changes in the dynamic world of electronics, where innovation never stops, and technology advances at a startling rate: the significance of safety. A Printed Circuit Board (PCB), an inconspicuous component essential to defining a device’s dependability, performance, and, most importantly, safety, is found at the core of every electronic gadget. A safe PCB design is more than just a technical necessity; it demonstrates superior engineering and a dedication to user safety.

The Basis for Safe Design:

Imagine a PCB as a complex network of streets that connects the city’s numerous components, directing traffic movement (electricity). A PCB’s layout and design must be precisely designed to prevent malfunctions and dangers, and a city’s road system must be well-planned to avoid traffic jams and accidents. When it comes to this, safe PCB design is important.

- Component placement:

Picture the arrangement of buildings in a city as the components on a PCB. Strategic positioning can decrease electromagnetic interference, avoid overheating, and promote effective communication between components. A safe PCB design ensures that sensitive components are insulated from potential sources of interference and that those high-power components are sufficiently separated to dissipate heat.

- Trace Routing:

On a PCB, the traces serve as the roads that link the various components. Traffic congestion (signal distortions) and accidents (short circuits) may happen on these roadways if badly built. A PCB design uses accurate trace routing for signal integrity and to avoid crosstalk between traces. Smooth signal transmission may be achieved by paying close attention to the spacing and orientation of the traces.

- Thermal Management:

Heat is electronics’ worst enemy. Inadequate heat dissipation can cause parts to malfunction, resulting in poor performance or even fires. In order to effectively disperse heat, a PCB design comprises elements like heat sinks, thermal vias, and the right spacing. The lifetime and dependability of the PCB are improved by maintaining components at ideal temperatures.

- Grounding and Signal Integrity:

Similar to how incorrect signal integrity and grounding procedures on a PCB might result in unexpected behavior. A PCB design ensures that signals flow as intended and lowers the possibility of noise, establishing clear channels for current return and lowering the possibility of system failure.

- Choosing the Components:

Components on a PCB must be chosen with the device’s intended usage in mind, much as buildings in a city must be built to endure diverse climates. Components are guaranteed to be certified for the appropriate voltage levels and environmental conditions by a safe PCB design. This avoids early failures and unforeseen malfunctions that can jeopardize security.

- Standards Compliance:

Every city has rules to guarantee public safety. PCBs must follow similar rules and restrictions. The usage of environmentally friendly materials and the general safety of the device is ensured by compliance with standards like RoHS (Restriction of Hazardous Substances) and UL (Underwriters Laboratories).

- Maintenance and documentation:

Cities have emergency plans and maps, and PCBs have paperwork and distinct marks. The appropriate labelling of components, connections, and crucial information is part of a PCBdesign safe. This facilitates maintenance, repairs, and troubleshooting, cutting down on downtime and possible risks. It is impossible to exaggerate the importance of PCB design in the contemporary day when electronic gadgets are present in every part of our lives. The safety of these gadgets, which range from life-saving medical equipment to standard consumer electronics, depends on the quality of their PCBs. To guarantee that each PCB they build is more than simply a circuit but a fortress of safety, engineers and designers are responsible for combining creativity with accuracy and innovation with prudence.

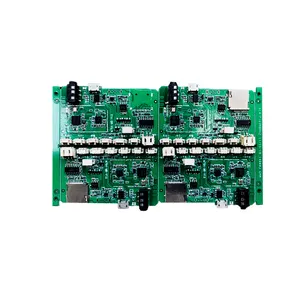

A safe PCB is the Industrial Automation Prototype PCB Assembly:

A safe PCB is essential in the constantly changing world of industrial automation, where accuracy and dependability are crucial. Industrial Automation Prototype PCB Assembly has completely changed how industries function by reducing procedures, increasing productivity, and assuring a secure working environment. The painstaking design and construction of printed circuit boards made especially for industrial automation applications is referred to as industrial automation prototype PCB assembly. These PCBs are more than just parts; they form the framework of complex equipment that powers contemporary production procedures. They stand out because of their relentless dedication to safety.

- Robust Design:

Industrial automation settings frequently face difficulties such as temperature changes, EMI, and high voltage situations. These aspects are taken into account in a PCB design for industrial automation, ensuring that the components are placed strategically to survive challenging circumstances without sacrificing performance.

- Fault Tolerance:

In an industrial context, a defective PCB can cause operations to be disrupted and provide safety issues. It incorporates redundancy and fail-safe features and focuses on fault tolerance in industrial automation prototype PCB assembly. This implies that even if a component malfunctions, the system may still run without endangering productivity or safety.

- EMI/EMC Shielding:

In industrial automation, where much electronic equipment coexists, electromagnetic compatibility (EMC) and electromagnetic interference (EMI) are serious issues. Advanced shielding methods and adequate grounding are used in PCB design to reduce EMI and ensure that signals are dependable and clear.

- Safety protocols:

Human contact and large machinery are frequently used in industrial automation operations. Safe PCBs provide facilities for security procedures such as sensor integration, interlocks, and emergency shutdowns. These precautions guarantee that activities can be stopped quickly in the event of any danger, safeguarding both employees and equipment.

- Robustness:

Robustness is necessary in industrial settings. Common difficulties include shock, vibration, and exposure to various factors. In order to survive the rigours of the industrial setting and save downtime due to maintenance or replacement, a PCB design for industrial automation uses durable materials and manufacturing procedures.

- Requirements Compliance:

Industries must adhere to strict safety and quality requirements. These guidelines are followed by Industrial Automation Prototype PCB Assembly, which guarantees that the finished item satisfies or surpasses legal specifications. This ensures that safety is given top priority during the design and production of the PCBs.

- Real-time Monitoring:

Safe PCBs for industrial automation frequently have this feature. This makes it possible to continuously track important indicators, enabling predictive maintenance and the early identification of potential problems that can endanger safety or efficiency.

- Automated Precision:

This assembly relies heavily on automation technologies to perform duties accurately. It includes equipment, computerized systems, and control mechanisms that all work together to provide precision that exceeds that of humans.

- Efficiency Improvement:

Enhanced efficiency and industrial automation go hand in hand. This assembly streamlines procedures reduces waste, and increases production in industrial processes. As a result, production significantly rises, and resource consumption declines.

- Safety Assurance:

Safety is always a top priority in industrial settings. This assembly includes automatic safety controls that react quickly to possible dangers, assuring the process’s productivity and the workers’ safety.

- Versatile Application:

The Industrial Automation Prototype PCB Assembly is used in a variety of sectors, including the production of machinery and information technology. Due to its versatility, enterprises of different shapes and sizes may take advantage of its efficiency-focused skills.

- Pioneer of Progress:

The assembly is proof of the Industrial Revolution’s influence on technology, according to the pioneer of progress. Accepting automation boosts productivity and propels the sector toward a future characterized by creative solutions and top performance.

Conclusion:

A safe PCB is more than simply a technological success in the field of industrial automation; it is a basic tenet that supports the reliability of procedures, prevents accidents, and ensures the safety of employees. The significance of Industrial Automation Prototype PCB Assembly cannot be emphasized as industries continue to adopt automation for increased efficiency and precision. Bridging the gap between innovation and safety it ensures that future factories run smoothly, effectively, and, most importantly, safely. The route from an idea to an operational electronic gadget is one that has been paved with diligence, skill and an unwavering dedication to safety. NewHonest defines and lays out clear objectives and benchmarks for environmental controls, and we continually assess the outcomes of environmental actions to make further advancements. With the cooperation of every worker in the production, we always manage environmental protection operations.