Exploring the Advantages of Printed Circuit Board Service in Contemporary Electronic Manufacturing Industries

What exactly is printed circuit board service?

The electronics industry depends on printed circuit board (PCB) services. Almost all of the electronic gadgets we use daily are built around PCBs designed, manufactured, and assembled using a broad range of procedures. A PCB is fundamentally a flat, rigid board having electrical channels etched or printed onto it that are constructed of non-conductive material (often fibreglass or composite epoxy). These connections—called traces—create a complex network that allows integrated circuits, transistors, resistors, and other electronic components to communicate and operate together. Printed circuit board service includes the following crucial steps:

Design:

The first step in the process is PCB design, where engineers use specialized software to arrange the layout of components and traces on the board while considering dimensions, shapes, and electrical specifications.

- Production:

After the design, the PCB goes through production, which entails making the actual board and etching or printing the electrical pathways onto it. Depending on the electrical gadget’s complexity, this can range from single-layer to multi-layer boards.

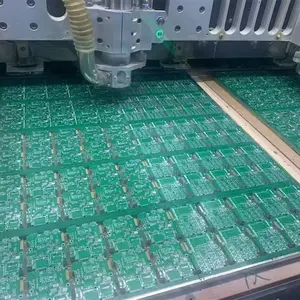

- Assembly:

Electronic components are soldered onto the board once the PCBs have been created, sometimes with automated machinery. To guarantee good connectivity and operation, this step is essential.

- Testing:

A crucial component of PCB services is quality control. Rigorous testing is carried out to verify that the constructed PCBs satisfy the requirements and operate dependably. In essence, PCB services efficiently and affordably support the creation of a wide range of electronic products, from smartphones and laptops to medical equipment and aerospace technology. Their accuracy, dependability, and design flexibility are vital in our technologically advanced society.

The positive aspects of Printed Circuit Board (PCB) Services:

Printed Circuit Boards (PCBs) are now the unsung heroes that keep our contemporary world running in today’s quickly evolving technological scene. Nearly all electronic devices, including computers, cellphones, and even the most complex medical equipment, are built around printed circuit boards (PCBs). The benefits of PCB services are apparent, even if they sometimes go overlooked. The importance of printed circuit board service in our technologically advanced world will be discussed in this article.

- Precision and Accuracy:

PCB services’ precision and accuracy are among the main benefits of hiring them. Due to the great level of accuracy used in PCB manufacturing, every electrical component is placed precisely where it should be. PCBs are the best option for intricate and small electrical devices since human wiring is practically impossible to produce at this degree of perfection. PCBs offer the precision and dependability necessary for maximum performance, whether in a basic calculator or a cutting-edge aerospace application.

- Space-Efficiency:

Since space is frequently limited in electronic systems, PCBs perform very well in this area. They make organising components compactly over several layers possible, effectively utilizing available space inside a device. Electronics makers may produce smaller, more portable, sleeker goods with PCBs, making them simpler to handle and carry. Miniaturization is a major trend in the industry.

- Cost-Effective Production:

The PCB manufacturing techniques have advanced dramatically, making them an affordable option for the manufacture of electronics. The assembly and production of PCBs are automated, lowering labour costs and reducing the possibility of human mistakes. Additionally, PCBs are simple to mass-create, which lowers the price per unit and helps both producers and customers.

- Enhanced Reliability:

In electronics, reliability is crucial, and PCBs are renowned for their sturdiness and long-term performance. PCBs have soldered connections that are extremely resilient to vibration and temperature changes, in contrast to conventional point-to-point wire, which is prone to wear and tear. This reliability is essential in vital applications like medical technology, automotive systems, and aerospace technology.

- Streamlined Prototyping:

PCB services simplify prototyping, allowing designers and engineers to test their ideas and designs quickly. Rapid prototyping with PCBs speeds up development cycles by reducing the time and expense of trial and error. This flexibility in product creation is crucial in today’s cutthroat market, where innovation frequently determines success.

- Freedom in Design:

PCBs provide a great level of design freedom. They are appropriate for various applications because they can be tailored to meet different forms, sizes, and complexity. PCB services can accommodate your unique design needs, whether you need a straightforward single-layer board or a multi-layer PCB with sophisticated routing.

- Better Electrical Performance:

PCBs are made with electrical performance in mind. Careful component placement and trace routing minimize electromagnetic interference (EMI) and signal loss. This improves signal integrity and lessens component cross-talk, eventually improving electronic equipment’s overall performance.

- Environmental friendliness:

PCBs have a benefit in today’s climate of rising environmental consciousness. They are frequently constructed from recyclable materials, and their compact form results in smaller, more energy-efficient gadgets. PCBs are a sustainable option in electronics production since they require less wiring and connections and contribute to less electronic waste.

Why Choose Us?

- Dongguan Wenshu Electronic Technology is a trustworthy PCB Assembly firm to OEM, having received investment from Hong Kong-based New Honest Group in 1997. We provide more flexibility, one-stop shopping, premium products, and first-rate after-sales care. Since then, we have established a 10,000-square-meter production facility with roughly 350 highly qualified workers. We are currently IATF16949, ISO9001, and Manufacturing Execution System (MES) certified. Wenshu has worked in the industrial control, automotive and high-end consumer electronics market sectors in Japan, Europe, North America, and the domestic market.

- The quality management system standard ISO 9001 is relevant to many different sectors. It assists businesses in setting up procedures that guarantee consistent product or service quality and client pleasure. A software program called a manufacturing execution system (MES) aids in the management and supervision of production processes on the shop floor. It offers real-time information, tracking, and monitoring of the manufacturing processes, which helps to increase productivity and efficiency. Wenshu presence on several continents, including Japan, Europe, North America, and the local market, is significant. This vast reach and client base suggest a global presence, which may help diversify your business and maintain competitiveness in different areas.

The Crucial Function of PCB Services in Electronic Devices:

Electronic gadgets are becoming a necessary component of daily life in the digital era, acting as anything from entertainment centres to communication tools and crucial tools in various businesses. The Printed Circuit Board (PCB), a key element that underpins all these cutting-edge devices, makes it all possible. Electronic device operation and dependability heavily depend on PCB services, which are crucial for these devices. This post will explore why printed circuit board service are crucial in the electronics industry.

- PCBs link and integrate the numerous electronic components that go into making up an electronic device, acting as the central nervous system of those devices. These parts, microprocessors, memory chips, sensors, and more, require systematic and effective communication. These connections may be made with the help of PCBs, enabling a smooth transfer of data and signals inside the device.

- When designing electrical equipment, space is sometimes at a premium. Because PCBs use so little space, components may be arranged closely in numerous layers. The development of svelte, transportable, and user-friendly electronics, from smartphones and tablets to wearables and IoT (Internet of Things) devices, depends on this shrinking.

- PCB services provide a degree of accuracy and precision that is hard to obtain through manual wiring or other techniques. Each electrical component is carefully positioned and linked during the design and manufacturing processes, minimizing the possibility of mistakes or malfunctions. This accuracy is essential in fields like aircraft technology, automotive systems, and medical equipment, where dependability is critical.

- PCB manufacturing techniques have advanced to provide electronics manufacturers with affordable production options. Automation decreases labour costs for PCB assembly and fabrication, and economies of scale further decrease manufacturing costs per unit. Both producers, who can build gadgets more economically, and customers, who can access cutting-edge technology at competitive costs, profit from cost efficiency.

- A high degree of design freedom is available with PCBs. They may be tailored to fit different forms, sizes, and complexity levels, making them appropriate for various applications. PCB services may accommodate certain design needs, whether a straightforward single-layer board or a multi-layer PCB with sophisticated routing.

- PCBs are made to maximize electrical performance. Signal loss and electromagnetic interference (EMI) are kept to a minimum by careful component placement and trace routing. The overall performance of electronic devices is eventually improved due to improved signal integrity and less cross-talk between components.

Conclusion:

Printed circuit board service is vital for electronic devices because of their crucial role in enabling connectivity, guaranteeing space efficiency, providing precision and accuracy, facilitating cost-effective production, enhancing reliability, streamlining prototyping, offering design flexibility, improving electrical performance, and promoting environmental sustainability. NewHonest advantages elevate PCB services to a crucial position at the core of the contemporary electronics sector, fostering innovation and powering the machinery that makes our world go round. Whether the smartphone in your pocket or the cutting-edge medical technology in a hospital, PCBs are the unsung heroes who enable it all.