Exploring the Benefits of PCB China Prototype: A Gateway to Efficient and Cost-Effective Manufacturing

What exactly is the PCB China prototype?

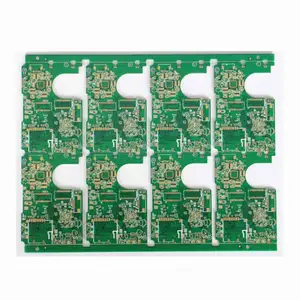

The basis of contemporary electronics, printed circuit boards (PCBs) link and support electronic components to ensure their performance. A prototype PCB is a crucial phase in the design and testing process for building new electrical gadgets or goods. Prototypes from PCB China are useful in this situation. Prototype printed circuit boards from PCB China are the early iterations of printed circuit boards produced in China for testing, validation, and iteration. Due to its cutting-edge technology, affordable manufacturing capabilities, and effective supply chains, China has become a major worldwide hub for PCB fabrication.

Before mass manufacturing, these prototypes let engineers, designers, and inventors physically evaluate and test their circuit designs. Early on in the development cycle, this aids in finding any design faults, technical problems, or performance constraints, ultimately leading to enhancements and optimizations. Prototypes from pcb China prototype are known for their short turnaround times, affordability, technical proficiency, and adherence to global quality standards.

Considering PCB’s Advantages Prototypes from China:

Modern electronics are built on printed circuit boards (PCBs), which are the fundamental framework for connecting and powering electronic parts. Prototyping is essential to assure performance, dependability, and cost-effectiveness while creating new electrical devices or goods. With a number of advantages that make it a top choice for innovators globally, China has established itself as a global leader in PCB production and prototyping. The benefits of hiring for a pcb china prototype will be covered in detail in this article.

- Cost-Effectiveness:

China has a long history of having affordable manufacturing costs, and PCB fabrication is no different. Cost factors are important when it comes to prototyping. Lower production costs are a result of China’s established supply networks, cutting-edge manufacturing skills, and inexpensive labour. This accessibility enables everyone, from established businesses to startups, to experiment and iterate on their ideas without experiencing undue financial burden.

- Timely turnaround:

In today’s quickly changing digital world, time-to-market is a crucial consideration. Manufacturers of PCB prototypes in China are recognized for their lightning-fast turnaround times. The nation’s vast industrial infrastructure and effective logistical networks make it possible to produce and distribute PCB prototypes quickly. Thanks to this adaptability, developers can quickly bring their thoughts to life and keep one step ahead of the competition.

- Technical Proficiency:

China’s PCB manufacturing sector has achieved incredible technological and professional strides. Chinese manufacturers make significant investments in R&D, using cutting-edge methods, tools, and supplies. This knowledge guarantees that PCB prototypes made in China are of the highest caliber and adhere to all technical specifications and industry standards.

- Volume Production Flexibility:

The pcb china prototype services have the adaptability to meet your demands, whether you’re a lone inventor working on a tiny idea or a business organizing a large-scale production run. Chinese producers can handle a range of production scales, from small prototype batches to large production runs, making it an excellent option for projects of all sorts.

- Integrated Support Ecosystem:

A strong ecosystem that supports the full product development process helps China’s PCB prototype sector. NewHonest manufacturers provide end-to-end solutions that speed up the prototype process, from design support and design-for-manufacturability (DFM) input through sourcing components and final assembly. This all-inclusive assistance solution reduces the difficulties and complexity involved in PCB prototyping.

- Certifications and Quality Assurance:

Contrary to popular belief, China places a high priority on quality assurance. Reputable PCB producers in China follow stringent quality control procedures and global norms. Additionally, a lot of manufacturers have accreditations like ISO and UL, which guarantee that the prototypes adhere to strict quality standards. The reliability, durability, and intended functionality of the PCB prototypes are all ensured by this emphasis on quality.

- Certifications and Quality Assurance:

Contrary to popular belief, China places a high priority on quality assurance. Reputable PCB producers in China follow stringent quality control procedures and global norms. Additionally, a lot of manufacturers have accreditations like ISO and UL, which guarantee that the prototypes adhere to strict quality standards. The reliability, durability, and intended functionality of the PCB prototypes are all ensured by this emphasis on quality.

Function Netcom Prototype PCB Assembly:

The Netcom Prototype PCB Assembly is a functioning powerhouse that can handle a wide range of communication needs.

- Excellence in Communication:

It offers multi-center data communication and dual-channel data transfer through GPRS and short messaging. This guarantees smooth and effective data exchange.

- Data Gathering:

The assembly is excellent at gathering serial device data from instruments, collectors, PLCs, and other sources, enabling thorough data analysis and usage.

- Remote Management:

Remote administration makes it easy to maintain and optimize your communication system. Take advantage of the ease of remote parameter setting and software updates.

Features of pcb china prototype:

- Industrial-Grade Design:

Constructed to resist even the worst outside conditions, this assembly thrives in trying circumstances and offers reliable performance when required.

- Reliability Assurance:

For a dependable communication experience, built-in hardware and software watchdogs ensure ongoing operation by averting crashes and dropouts.

- Data Transparency:

By supporting data transparent transmission, seamless data transfer is made possible, facilitating quick and effective data interchange.

- Domain Name Resolution:

The ability to resolve domain names makes administering and navigating the communication network easier and more logical.

User-friendly customization: The assembly supports a variety of configuration software and enables users to create specialized software systems, increasing flexibility and adaptability.

What is the significance of Netcom Prototype PCB Assembly?

Creating cutting-edge electronic products needs a strong basis in the quick-paced world of technology, where innovation is continual. Electronic goods’ dependability and functionality are greatly influenced by printed circuit boards (PCBs). Selecting the appropriate strategy is essential when developing and constructing PCBs for network communication (Netcom) devices. This blog post will explore the benefits of Netcom Prototype PCB Assembly being a superior option for engineers and innovators.

- Intricate PCB designs are required for Netcom equipment, including routers, switches, and communication modules, to provide high-speed data transfer, signal integrity, and network stability. Services for Netcom Prototype PCB Assembly are designed precisely to meet these needs. Engineers knowledgeable in Netcom technology can produce prototypes perfect for smooth network communication by understanding the complexities of signal routes, impedance management, and noise reduction.

- Netcom Prototype PCB Assembly provides a complete solution by combining PCB design and assembly. The development process is streamlined using a holistic approach, reducing the likelihood of design requirements and assembly execution needing to be in sync. Teams from the design and assembly phases work together to ensure the prototypes are prepared for manufacture and have been optimized for both.

- Being competitive in the rapidly changing world of networking technologies requires quick iteration. Rapid prototyping is a service provided by Netcom Prototype PCB Assembly that shortens the time it takes to turn ideas into workable prototypes. This speed accelerates the innovation cycle because engineers may test and improve their designs more often, which leads to higher-quality final goods.

- Netcom Prototype PCB Assembly provides a complete solution by combining PCB design and assembly. The development process is streamlined using a holistic approach, reducing the likelihood of design requirements and assembly execution needing to be in sync. Teams from the design and assembly phases work together to ensure the prototypes are prepared for manufacture and have been optimized for both.

- Reliability is essential in Netcom devices where network outages can cause serious disruptions. Reputable Netcom prototype PCB assembly services give stringent quality control procedures a top priority. The dependability and lifespan of the prototypes are ensured, even in challenging networking situations, by closely monitoring every stage of the manufacturing process, from material selection to assembly methods.

- For remote sites with great distances, the wireless technique greatly shortens project cycles and makes rapid setup through antenna installation possible.

- Unlike wired communication, wireless transmission can operate in various conditions, providing continuous connectivity in places where wiring is not feasible.

- With this assembly, expanding your communication network is simple. Connecting additional hardware to the wireless data transmission station allows for better scalability without requiring labour-intensive rewiring.

Conclusion:

It is indisputable that choosing PCB prototypes from China has advantages. China is a top choice for PCB prototypes because of the country’s competitive pricing, quick turnaround times, technical know-how, flexibility, extensive support network, quality assurance, and efficient communication. China’s PCB manufacturing sector provides the tools and resources required to convert creative ideas into working prototypes, regardless of the scope of your project or your degree of experience. Utilizing China PCB prototype services may be a game-changer for innovators wanting to remain ahead in the cutthroat market as the electronics industry develops. NewHonest abide by all laws and rules that pertain to environmental preservation. We eliminate waste and work to advance and enhance manufacturing techniques for pollutant reduction. We tighten regulations on dirty water, exhaust fumes, noise, and solid waste to reduce environmental impacts.