China Flexible Circuits PCB Manufacturers, Suppliers – Wenshu

Wenshu stands as a distinguished specialist in the manufacturing of Flexible circuit PCBs and a proficient PCB assembly provider located in China. Our extensive experience in Flexible Circuits PCB manufacturing ensures the delivery of top-notch products, including flexible circuits, flex circuits, rigid-flex circuits, rigid-flex boards, and an array of related offerings. CHINA FLEXIBLE CIRCUITS PCB MANUFACTURER

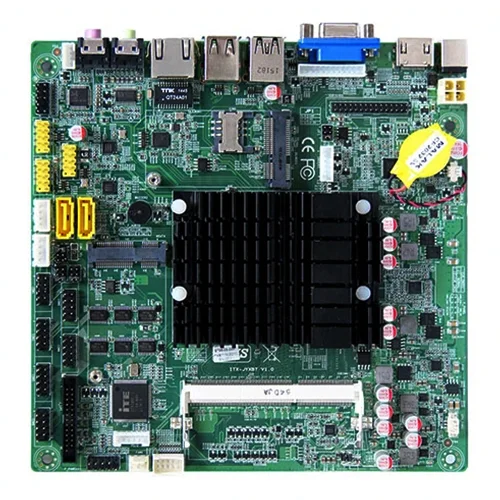

High-Density Interconnect PCB

Understanding High-Density Interconnect PCBs (HDI PCBs)

A High-Density Interconnect PCB, commonly known as an HDI PCB, is a type of printed circuit board characterized by its abundant through-hole and surface mount components. It proves to be an excellent choice for applications demanding high speeds and densely packed components.

HDI PCBs are typically constructed using an FR4 substrate, featuring multiple layers of copper on both sides. Among these layers, the inner core layer facilitates component interconnections, while the outer ground plane layer serves as a shielding conductor. This design offers superior capabilities for mitigating electromagnetic interference (EMI) and preserving signal integrity compared to traditional single-sided PCBs.

The Popularity of High-Density Interconnect PCBs

The density of interconnections on a PCB plays a pivotal role in determining assembly speed and the capacity to route numerous signals concurrently. Higher density translates to enhanced signal transmission speed and improved signal integrity. The maximum achievable interconnect density hinges on various factors, including signal frequency, routing techniques, copper thickness, and copper plate thickness. Current industry trends are geared towards boosting density through the adoption of high-conductivity copper materials like CMP, HASL, or OSP (one-side plating) technologies.

PCB Manufacturing Service

Wenshu PCB Manufacturing specializes in offering high-quality PCB assembly services at competitive prices with a commitment to on-time delivery. For over 26 years, we have been committed to offering products and services that meet our customers’ expectations. CHINA FLEXIBLE CIRCUITS PCB MANUFACTURER

PCB Prototype

Our PCB Prototype service makes it easy for you to order individual printed circuit boards without having to go through the lengthy design and manufacturing process.

The PCB fabrication process is intricate and encompasses various stages. Establishing a dedicated company for this process is often more practical than attempting to manage it independently. However, if you are in need of PCBs for your own products and have specific requirements, we can help.

SMT Assembly

One advantage of SMT assembly is that it allows for more dense packing of components on the PCB, resulting in smaller circuit boards with more components per unit area. This allows for smaller devices such as mobile phones or GPS units to be made on one PCB rather than several discrete boards. Another advantage is that interconnections between components can be made much shorter than with through-hole mounting which requires long leads that may interfere with one another or be damaged during handling by the user or during assembly/disassembly processes.

FR4 PCB

We are a leading FR4 PCB manufacturer and supplier based in China, committed to delivering top-notch product quality and swift delivery.

FR4 PCBs are the predominant material used in printed circuit boards (PCBs). These laminated glass-reinforced epoxy laminates excel as electrical insulators while boasting exceptional mechanical strength.

Our FR4 PCBs are remarkably flexible, making them easy to bend into various shapes without risk of cracking or breaking. This flexibility also renders them suitable as substrates for flexible electronics and other applications that demand bendability.

Multilayer PCB

We offer multilayer PCBs (up to 14 layers), which are mainly used for the following applications:

Our products are used in the medical, communications, semiconductor and electronic components, consumer electronics, aerospace & defense, automotive & transportation, oil & gas exploration & production, and utilities industries.

PCBA (Printed Circuit Board Assembly)

PCBA, or Printed Circuit Board Assembly, represents a critical facet of the PCB industry. It encompasses the process of populating electronic components onto a printed circuit board (PCB). PCBA can be performed manually, with components placed by hand, or with specialized tools like tweezers. You can also use pick-and-place machines or conveyor systems to automatically place the components.

Low-Cost Flexible Circuits PCBs

We offer a diverse selection of flexible circuit PCBs and flexible printed circuit boards to suit your project’s needs, with the flexibility to customize their size, shape, and thickness. We also have the capability to produce custom flexible circuits according to your specific designs or artwork.

Our cost-effective flexible circuits provide the opportunity to incorporate smart features into a wide range of your products. We can tailor these products to your requirements by integrating components like LEDs, switches, buttons, and more.

How to manufacture a flexible circuit board?

The copper foil or CCL that makes up flexible circuit boards typically adheres to a non-conductive substrate, such as polyimide (Kapton), polyethylene terephthalate (PET), polycarbonate (PC), or polyester film.

The common method for creating flexible circuit boards involves utilizing photolithography to generate patterns on the base material’s surface and then etching away the unnecessary portions. The etched regions serve as conductors, forming the circuitry, while the remaining material acts as an insulator, preventing short circuits between conductors or with nearby conductors on the board.

What are the applications of flexible circuit boards?

Flexible circuit boards find applications across various industries. With the increasing adoption of electronics in many sectors, flexible circuit boards offer a cost-effective and efficient means to automate specific tasks. For instance, the automotive industry employs them as motherboards for intelligent vehicles, while the medical field has also identified applications for them. With over 26 years of experience, we have a strong track record in manufacturing flexible circuits and PCBs for a diverse clientele.

Why choose Wenshu for flexible PCB fabrication?

Wenshu, a reputable China-based flexible circuit board manufacturer, delivers high-quality flex circuits at competitive prices. Our company boasts more than 26 years of experience in producing flexible circuits and PCBs for numerous global brands, making us a trusted partner for your flexible PCB needs.

Ultra-fine line and space

The ultra-fine line and space-flexible circuits industry is growing due to the increasing demand for ultra-thin and narrow circuit boards. These circuits excel in achieving extremely small thicknesses of 0.1mm or less. They find wide-ranging applications in medical devices, wearable electronics, portable electronics, IoT products, and various other fields.

Precision Patterning

Precision patterning refers to the capacity to rapidly create circuit boards with exceptionally fine layers. It involves employing a glass master that undergoes an etching process to eliminate exposed portions while preserving unexposed areas. These technologies enable the development of ultra-fine features in flexible circuits.

Creating a glass master for a photomask involves exposing photosensitive photoresists to ultraviolet (UV) light through a mask pattern, transferring the image onto the glass master’s surface. Subsequently, the glass master goes through an etching process, removing the exposed portions while retaining the unexposed areas. The resulting master acts as an etch mask for crafting circuits on a flexible substrate.

Ultra-Low Warpage

We utilize cutting-edge technology to produce flexible PCB boards with minimal warping, ensuring high performance. Our Flexible Circuits also exhibit exceptional heat resistance, withstanding temperatures of up to 200℃. This feature makes our Flexible Circuits particularly well-suited for automotive applications.

High Layer Count and Performance

Modern PCBs necessitate flexible circuit boards with elevated layer counts and performance capabilities. Wenshu offers flexible circuit boards designed to meet these demanding requirements, delivering high-performance characteristics to address the evolving needs of the industry.

Conformal Coating Service for PCBs

We offer comprehensive conformal coating services for your PCB boards. This process involves applying a protective conformal coating to shield the boards from moisture and other environmental factors, which can damage them and reduce their reliability.

Key Benefits

Conformal coatings deliver a multitude of advantages, including:

- Protection against moisture, corrosion, and contaminants.

- Mitigation of thermal cycle fatigue.

- Reduction of impedance and augmentation of component power handling capabilities.

- Control over surface resistivity (polarization).

Most Common Types and Features

Conformal coatings are a popular choice for many electronic devices. These coatings protect the electronics from moisture, chemicals, and other hazards. Conformal coatings are available in various thicknesses, tailored to specific application requirements. They are applied via spraying onto components, sometimes necessitating an adhesive layer to ensure proper adhesion.

CONCULUSION

Our offerings encompass a diverse array of electronic design services, encompassing PCB prototyping, PCB assembly, and comprehensive PCBA solutions. Our overarching objective is to furnish exceptional products and services that remain competitively priced. We work hard to maintain lasting relationships with our clients, who are always happy with the quality of our offerings and services. CHINA FLEXIBLE CIRCUITS PCB MANUFACTURER