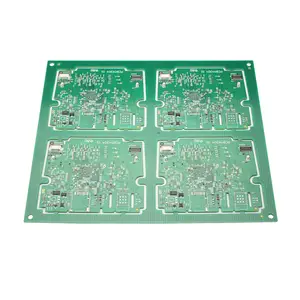

NewHonest: Leading the Way as a Quick PCB Manufacturer

What is exactly quick pcb for?

“Quick PCB” probably relates to creating prototypes and finished printed circuit boards (PCBs) as rapidly as possible. A printed circuit board, which offers a platform for connecting and sustaining numerous electrical components, is a key part of electronic devices. Printed circuit boards (PCBs) play a crucial function in the ever-changing world of electronics. The functioning and performance of almost all electronic devices are determined by these complex boards, which act as their backbone. However, the traditional PCB manufacturing process frequently entails lengthy lead times and iterative delays that can discourage innovation and limit development. Here comes NewHonest, a quick pcb manufacturer in electronics manufacturing who is revolutionizing PCB production with our dedication to rapid turnaround times. In this blog article, we’ll look at how NewHonest is advancing efficiency, altering the PCB manufacturing industry, and advancing technology.

How NewHonest is revolutionizing PCB manufacturing with quick turnaround times?

Rapid product development is a crucial success factor in the fast-paced world of electronics and technology. Here comes NewHonest, a pioneer in the PCB manufacturing sector, revolutionizing how companies bring their creations to life with blazingly quick turnaround times. We’ll explore how NewHonest dedication to short turnarounds is revolutionizing PCB manufacturing in this blog article, as well as the effects this has on the sector as a whole.

The need for speed:

The success of every electrical product depends on how quickly it can be brought to market. Traditional PCB manufacturing procedures sometimes entail protracted design iterations, sluggish prototyping, and extensive production lead times. As a result, inventors took a lot of work to satisfy customer demand and profit from new trends. Recognizing this gap, NewHonest set out to close it with its innovative PCB manufacturing process. They have drastically shortened lead times without sacrificing quality by simplifying every process stage, from design to production.

The Paradigm Shift of NewHonest

In response to these difficulties, NewHonest, quick pcb manufacturer, has evolved as a transformative force, completely reinventing PCB manufacture. We have shortened the traditional production timeline by merging cutting-edge technology and creative business models, allowing businesses to hasten the development of our products.

- Automated Design Validation:

We use state-of-the-art software for design validation automation. Before going into production, this proactive technique finds probable mistakes and inconsistencies in PCB designs. Early problem detection reduces the need for several design iterations, which results in considerable time savings.

- Instant Ordering and Quoting:

The traditional ordering and quoting procedure can be a drawn-out affair. This process is streamlined by the NewHonest digital platform, which provides immediate quotations depending on design requirements. The early manufacturing phases are accelerated by the lack of lengthy communication loops caused by this quick pleasure.

- Swift Prototyping:

We provide accelerated turnaround times for PCB prototypes because we understand the need for rapid prototyping. This enables designers and engineers to quickly test ideas, iterate on designs, and make improvements in a shorter amount of time.

- Modern production Equipment:

Our dedication to innovation is seen in its cutting-edge production tools. Faster and more accurate PCB fabrication is made possible by automated assembly lines, precise drilling equipment, and cutting-edge soldering methods.

- Effective Supply Network Management:

On-time production depends heavily on a well-oiled supply network. We have improved supply chain management and encouraged supplier strategic partnerships. This helps to minimize production delays brought on by material shortages by ensuring a consistent supply of the supplies needed.

The Crucial Elements of Quick PCB Manufacturing

The pace at which goods are produced and brought to market is crucial in the quickly changing field of electronics, where invention drives advancement. The need for printed circuit boards (PCBs), crucial parts of almost all electronic gadgets, is equally urgent. Quick PCB manufacturing has emerged as a game-changer in this dynamic climate, allowing businesses to move quickly to grasp opportunities and meet customer needs. Let’s examine the essential features of rapid PCB fabrication and how it affects the market.

- Design iteration and rapid prototyping:

Rapid prototype and design iteration are the first steps towards quick PCB production. Prototyping quickly enables designers and engineers to test ideas, see possible problems, and make required adjustments early in development. This iterative method promotes innovation by fostering experimentation and examining numerous design choices.

- Verification of Automated Design:

A crucial component of efficient PCB manufacturing is automated design verification. Using sophisticated software tools, designs may be checked for flaws, consistency difficulties, and possible production problems. Early detection of these problems reduces the need for design amendments and speeds up the production process.

- Ordering and Instant Quoting:

Quick PCB manufacture is characterized by efficiency in quoting and ordering. Modern PCB producers frequently provide online platforms where consumers may enter their design requirements and get immediate quotations. This ends the delays brought on by manual quotation procedures and helps clients to reach choices more quickly.

- Simplified Manufacturing Techniques:

Production procedures that are simplified and effective are essential for quick PCB manufacture. Faster and more precise PCB creation and assembly are made possible by automated assembly lines, high-precision drilling equipment, and cutting-edge soldering procedures. With the help of these cutting-edge procedures, PCBs are made more quickly and with less waste and rework.

- High-Quality Results:

Quality is not sacrificed with rapid PCB production. In reality, the emphasis on efficiency frequently encourages innovative production techniques that raise the general standard of the resulting PCBs. The finished product will meet or surpass industry requirements thanks to automated procedures and rigorous quality control tests.

- Flexibility for Design Modifications:

Design modifications are unavoidable in a field that moves quickly. The ability to handle these modifications with minimal delay is provided by quick PCB manufacture. This capacity to adjust to changing design needs facilitates a more efficient product development process.

Why is NewHonest a leading company in producing PCBs?

The complex world of printed circuit boards (PCBs) is the bedrock of innovation in the dynamic field of electronics. Nearly every electrical gadget, from cell phones to industrial machines, is built around these fundamental parts. In this environment of ongoing development, NewHonest, a quick pcb manufacturer that has established itself at the forefront of PCB production, has emerged as a shining light. In this blog article, we’ll explore the factors that have helped NewHonest become a market leader in PCB manufacturing and revolutionize the sector with its dedication to excellence, innovation, and customer satisfaction.

A dedication to excellence

Our persistent dedication to quality is one of the pillars of our leadership in PCB manufacturing. In a field where accuracy and dependability are crucial, NewHonest has established the bar. Every PCB that leaves its facilities will satisfy the highest standards of quality and performance thanks to our manufacturing process, founded on meticulous attention to detail.

Modern Manufacturing Technologies

NewHonest investment in cutting-edge manufacturing technology is the key to its success. We have adopted automation and cutting-edge equipment to optimize production processes, increasing accuracy and efficiency. Every step of our production process, from automated assembly lines to high-precision drilling equipment, is created to produce quality PCBs quickly.

Innovative prototyping and design

Innovation from NewHonest goes beyond production tools; it embraces the entire nature of design and prototyping. We provide a rapid prototyping solution that enables engineers and designers to realize their ideas swiftly. With this strategy, the product development cycle is sped up, allowing companies to test, iterate, and improve their designs at a never-before-seen rate.

A rapid turnaround

In a time where efficiency is crucial, we have been a leader in offering rapid turnaround times for PCB manufacture. We have drastically lowered lead times by combining automated procedures, effective supply chain management, and simplified operations. Due to our client’s capacity to produce goods quickly, we can stay ahead of the competition and react quickly to market and technology changes.

Client-Cantered Approach

In large part, our success may be credited to our customer-focused strategy. We place a high value on getting to know our clients well, comprehending their particular needs, and meeting those needs with solutions. With a focus on the consumer’s needs, we have developed a following of devoted customers who see NewHonest as a trustworthy partner in their quest for innovation.

In the Face of Change, Agility

Adaptability is essential in the changing world of electronics. By staying ahead of industry trends and technical developments, NewHonest thrives in this area. We continually spend money on research and development to keep our products current and cutting-edge. Our reputation as a thought leader and trendsetter has been cemented by this proactive approach to remaining current with developments in the business.

Sustainable Behavior

The technological expertise of NewHonest is only one aspect of our leadership; we are also committed to sustainability. NewHonest has included environmentally friendly procedures in our production operations in an age where environmental responsibility is crucial. This demonstrates our dedication to the environment and resonates with companies and clients that place a high value on sustainable alliances.

Industry Awards and Recognition

Recognition from peers and experts is a sign of a great industry leader. The electronics industry has praised and awarded NewHonest for their excellent PCB fabrication work. These accolades confirm their knowledge and establish them as a business that continually goes above and beyond.

Conclusion:

A new age of efficiency and speed has arrived because of NewHonest creative approach to PCB fabrication. We have established ourselves as a technical innovation catalyst by solving the issues with conventional production techniques. With an emphasis on quick prototyping, cutting-edge technology, and seamless supply chain management, NewHonest enables businesses to turn their ideas into reality quickly. Our dedication to short turnaround times opens the door for a future where creativity knows no limitations as technology advances.