Component Sourcing

Benefit from our robust and dependable supply network, meticulously curated with the industry’s most trusted suppliers. These suppliers consistently deliver high-quality components for every project we undertake. Our seasoned procurement team possesses an in-depth market understanding, guaranteeing the availability of essential components at competitive prices.

Engineering

Prior to initiating the production of PCB assembly prototypes, we conduct a comprehensive Design for Manufacturability (DFM) analysis. This meticulous assessment ensures the elimination of any potential manufacturing issues. Collaborating closely with you, our engineers provide optimal solutions that not only reduce costs but also enhance overall productivity.

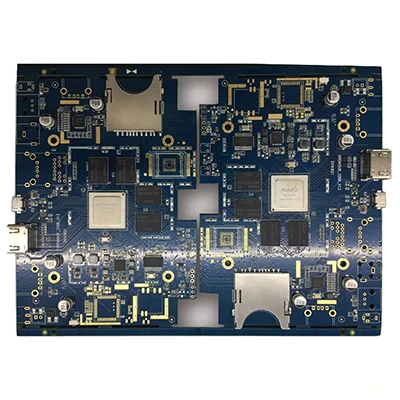

Prototype PCB Assembly

Our repertoire includes prototype assembly services catering to an array of PCB types, including high-frequency, HDI, Rigid, Rigid-flex, Flex, and Multi-layer PCBs. These prototype PCB assembly services find extensive application across diverse sectors such as automotive, industrial, medical, and electronics.

Testing

The quality of our PCB assembly prototypes is paramount. To ensure this, we subject them to a battery of meticulous testing and inspections. These include:

- Flying probe testing

- In-circuit testing

- X-Ray inspection

- Automated Optical Inspection (AOI)

- Visual inspection

Each testing methodology contributes to the comprehensive evaluation of our PCB assembly prototypes, assuring their reliability, functionality, and adherence to the highest quality standards.