Wenshu: Your One-Stop PCBA Prototype Factory

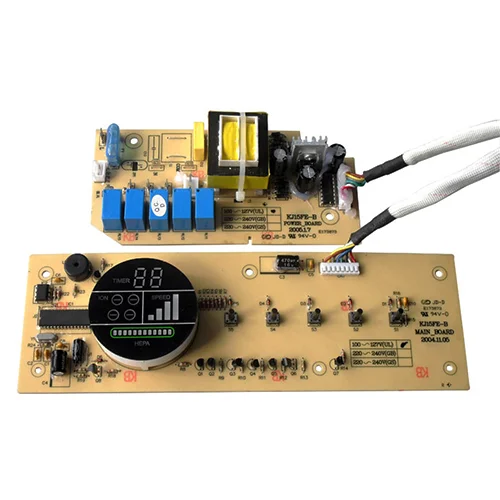

Wenshu provides a full range of services, including fabrication, assembly, design, and prototyping. We work in the Industrial Control, Automotive, and High-End Consumer Electronics market sectors in Japan, Europe, North America, and the Domestic Market. PCBA PROTOTYPE FACTORY

We offer a full range of services, from quick turn prototypes and small to medium batch production. Our factories have been in business for over 26 years and have a reputation for quality, reliability, and on-time delivery. We can meet all your PCB needs, from simple single-sided boards to complex multi-layer boards with stacked components and blind vias.

Wenshu, Your Trusted Partner in PCB Assembly Manufacturing

Your One-Stop PCBA Prototype Factory

We are a professional PCBA manufacturer and PCB prototyping service provider. We can help you to design and fabricate your prototype PCBA with the best quality and low cost. Our experienced engineers can make prototypes and small batch production at the same time, which is really helpful for fast-tracking your project.

1) High-Quality PCB Prototypes – Available in all popular sizes, materials, and thicknesses, including FR4, CEM-1, CEM-3, CEM-3V, Flexible PCBs etc. Our prototype service includes both single-layer and multilayer circuit boards.

2) Low Cost – We offer our customers the lowest price in the industry with a great quality control system & strict process in order to meet customers’ satisfaction.

Mission statement emphasizing the company’s role as a one-stop solution for PCB prototypes.

We have been running our factory for over 26 years and have rich experience in manufacturing different kinds of electronic products. With our own engineers, we are able to design your own PCBs according to your requirements.

Our main products include:

1)Flexible circuit boards (Flexible Printed Circuit boards)

2) Rigid circuit boards (Rigid-Flex)

3) Aluminum-embedded circuit boards (Aluminum Embedded Flexible Printed Circuit Board)

4) Multilayer PCBs (Multilayer Flexible Printed Circuit Boards)

5) Circuits embedded into metal enclosures (Metal embedded printed circuits).

PCBA Prototype Services

1. PCB fabrication

PCB fabrication is the process of creating a printed circuit board (PCB). PCBAs are used in a wide variety of applications including telecommunications, automotive systems, aerospace, and many other industries.

2. Component sourcing

The goal of component sourcing is to find parts that are suitable for your application at an acceptable price. Components come in many different types and sizes, so finding the right one can be difficult if you don’t know where to look or what to ask. It’s important to consider any constraints on your design before you begin sourcing parts.

3. PCB assembly

The main advantage of having your PCBs assembled by us is that we have years of experience in assembling PCBs. We also have all the necessary tools, machines, and equipment required for this process and we can therefore guarantee high-quality output at all times.

4. Testing and quality control

Our expert engineers use state-of-the-art equipment and techniques to test the functionality of your boards during the manufacturing process. We can also provide testing services for your final product, once it has been assembled.

5. Rapid turnaround times

If you are in the process of developing a new product and need to test it out before creating a mass production run, our PCB prototyping services can help you do just that. At Wenshu, we offer two levels of PCB assembly prototyping services: standard and rapid turnaround times (usually within 24 hours).

Our standard service provides you with one prototype board per week, while our rapid turnaround time option allows you to receive your completed prototype within 24 hours! PCBA PROTOTYPE FACTORY

Technology and Capabilities

Advanced Equipment and Technology

The latest in PCB prototyping technology is used to create our prototypes. We use a pick-and-place machine to assemble the parts on the board, ensuring they are placed in the exact location needed.

Pick & Place Machine: This machine takes a component from its tray and places it on a circuit board. It can handle small components like resistors and capacitors, as well as significant components like chips, making it very versatile. It uses suction cups to pick up the parts and place them where they belong on the board.

Laser Engraver: This machine uses an infrared laser to cut away copper from a printed circuit board (PCB). It can be used for creating traces and vias (holes) on your PCB when designing a new product or repairing an existing one.

High-quality PCBs, Delivered Quickly And In Bulk

We have achieved a number of technological milestones in our journey towards developing an all-encompassing, automated process for PCB manufacturing. This has enabled us to consistently deliver high-quality products that meet the stringent requirements of our customers.

Our state-of-the-art machinery and equipment, coupled with our in-house R&D team, enables us to deliver high-quality products at competitive pricing. We can also handle various types of PCBs such as single-sided, double-sided, multi-layer, and rigid flex boards.

Ordering and Prototyping Process

How customers submit PCB designs and component requirements.

The first step in the ordering process is to submit your design file and component requirements. You can do this by uploading your files, or by filling out our online template and sending it over to nhsales@newhonestgroup.com.

We then review your design for manufacturability and provide feedback on how we can help you improve it. Once we get all of the necessary files from you, we can start working on a prototype of your PCB.

After we have reviewed your design files, we will send you an estimated price quote for your PCBs. Once you accept this quote, we will begin manufacturing your boards. During manufacturing, we will send periodic status updates via email so you know exactly what’s going on with your order at all times. PCBA PROTOTYPE FACTORY

Quality Assurance

Commitment to Maintaining High-quality Standards

A commitment to maintaining high-quality standards is the core of our business. We understand that you may be concerned about the quality of our products and services.

Our Quality Assurance Department has been established to ensure that standard operating procedures are followed in all areas of our business. The Quality Assurance Department will ensure compliance with company policies and procedures, customer requirements, and regulatory requirements.

Our Quality Assurance Department will also monitor customer complaints and provide timely feedback to management regarding processes or products that may need improvement.

Inspection and Testing Processes to Ensure Functionality and Reliability

Various inspections are carried out to ensure that products meet the customer’s requirements, specifications, and standards. Inspections may be done by humans or machines in order to detect defects that the human eye cannot detect.

CONCLUSION

We may be the alternative you are looking for and we may be suitable for your project. Wenshu has been around since 1997 and we pride ourselves on a high-quality, turn-key prototype PCB assembly service tailored to your individual needs. We have large capacity solder paste stencil set up with high precision dispensing robots, surface mount technology equipment, wire wrap machines as well as reflow ovens and industrial x-ray machines. PCBA PROTOTYPE FACTORY

Our customer’s PCB assemblies are always made in-house by our professional circuit board assemblers in our clean room area. Each PCBA is both visually inspected and tested with an x-ray machine to ensure zero defects at the lowest possible price.