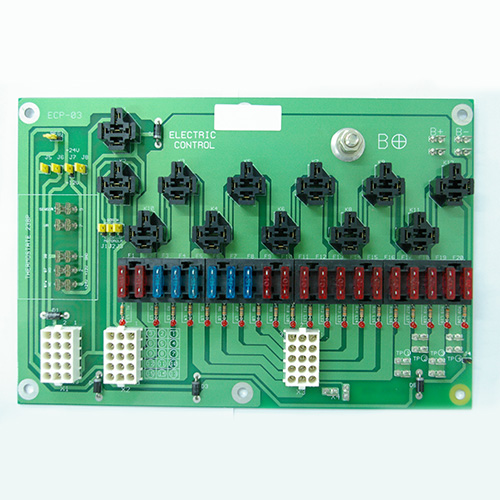

Electronic Control Main Board

The power control board is a device that provides current voltage to electronic equipment, also known as a power controller, which provides control of the current required by all components in the power supply. The size of the power supply, the stability of the current and voltage are directly affected by the power control board.

| Layers | 1~32 layers |

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Size | 50*50mm~510*460mm |

| Min Package | 01005 (0.4mm*0.2mm) |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

Prototype to Full Turn-Key Assembly

Through-Hole Lead-Free Wave Soldering

Best Price, Genuine Components

Quality Accreditation ISO9001

-

Description

-

Specification

Introducing our state-of-the-art Electronic Control Main Board – the heart of precision and efficiency for your electronic systems. Designed to empower seamless control and management, this main board stands as a pinnacle of technological advancement, ensuring your equipment operates flawlessly and precisely.

Key Features:

- Unparalleled Control: The Electronic Control Main Board offers unparalleled control over your electronic systems, enabling precise manipulation and optimization of various functions.

- Multi-Layer Integration: With the ability to integrate multiple layers of functionality, this main board streamlines complex processes, reducing the need for multiple components and connections.

- Sensory Precision: Equipped with advanced sensor interfaces, the main board interprets real-world data with precision, enabling your system to respond intelligently to changes in its environment.

- Robust Connectivity: Seamlessly communicate with peripherals and external devices through various communication interfaces, ensuring a cohesive and connected ecosystem.

- Adaptive Configuration: The main board’s adaptive configuration capability allows it to accommodate evolving requirements, providing a future-proof solution for your electronic control needs.

- User-Friendly Interface: Experience user-friendliness at its finest with an intuitive interface that simplifies configuration, monitoring, and control, making operation hassle-free.

- Enhanced Security: Your data and system integrity are paramount. The main board incorporates advanced security measures to safeguard against unauthorized access and data breaches.

Our expertise extends to precise PCBA and through hole assembly, with meticulous IC pre-programming, function verification, and burn-in testing for flawless functionality. Embrace a holistic approach with our complete unit assembly, incorporating plastic, screen, metal enclosures, membranes, coils, wire harnesses, and more. We accommodate projects of diverse sizes, offering flexibility for both small volumes and high-mix models. Quality remains paramount through rigorous Advanced Optical Inspection (AOI), In-Circuit Tests (ICT), and intricate placement of components like BGAs.

| ltem | Capability |

|---|---|

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Lead Time | 24 hours expedited service can be offered. 3- 4 days normally for PCBA prototype orders. We will give you an accurate lead time when we quote for you. |

| Size | 50*50mm~510*460mm |

| Board Type | Rigid PCB, Flexible PCB, metal core PCB |

| Min Package | 01005 (0.4mm*0.2mm) |

| Max Package | No limit |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

| Surface Finish | Lead/Lead-free HASL, Immersion gold, OPS, etc. |

| Assembly Types | Surface mount (SMT), Through-hole (DIP), Mixed Technology (SMT & Thru-hole) |

| Component Sourcing | Turnkey (All components sourced by Wenshu), Partial turnkey, Kitted/Consigned |

| BGA Package | BGA Dia. 0.14mm, BGA 0.2mm pitch |

| SMT Parts Presentation | Cut Tape, Partial reel, Reel, Tube, Tray, Laser-cut Stainless Steel |

| Cable Assembly | We supply custom cables, cable assemblies, wiring looms/harnesses and power leads for various industries including automotive, security, mining, medical and entertainment. |

| Stencil | Stencil with or without frame (offered free by Wenshu) |

| Quality Inspection | Visual inspection; AOI checking; BGA placement – X-RAY checking |

| SMT Capacity | 3 Million~4 Million Soldering Pad/day |

| DIP Capacity | 100 Thousand Pins/day |