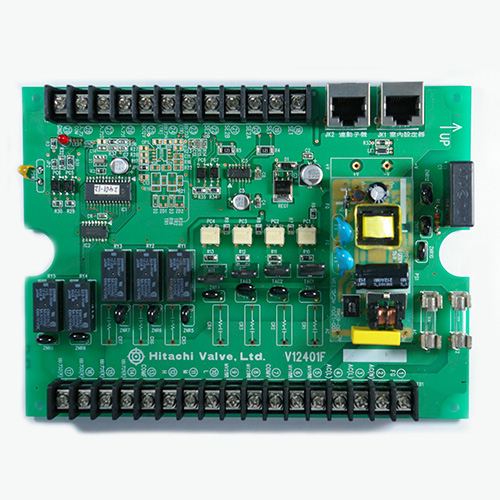

Industrial Power Main Board

The power control board is a device that provides current voltage to electronic equipment, also known as a power controller, which provides control of the current required by all components in the power supply. The size of the power supply, the stability of the current and voltage are directly affected by the power control board.

| Layers | 1~32 layers |

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Size | 50*50mm~510*460mm |

| Min Package | 01005 (0.4mm*0.2mm) |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

Prototype to Full Turn-Key Assembly

Through-Hole Lead-Free Wave Soldering

Best Price, Genuine Components

Quality Accreditation ISO9001

-

Description

-

Specification

Introducing our cutting-edge Industrial Power Main Board – the cornerstone of robust and efficient power distribution for your industrial operations. Engineered to elevate performance, enhance reliability, and ensure seamless power management, this main board is the ultimate solution for powering your machinery, equipment, and processes with precision.

Key Features:

- Reliable Power Distribution: Our Industrial Power Main Board is designed to efficiently distribute power across multiple circuits, ensuring a consistent and stable supply to critical equipment. This reliability minimizes downtime and maximizes productivity.

- Robust Build: Built to withstand the demands of industrial environments, the main board boasts a rugged construction that can endure varying temperatures, vibrations, and harsh conditions. This durability ensures consistent operation even in challenging settings.

- Advanced Circuit Protection: Safety is paramount in any industrial setting. Our main board incorporates advanced circuit protection mechanisms such as surge suppression, short circuit prevention, and overload safeguards. This protects both equipment and personnel from potential hazards.

- Modular Configuration: Customization is key. The main board offers a modular configuration, allowing you to tailor the setup to your specific power distribution needs. This flexibility ensures optimal compatibility with your existing infrastructure.

- Remote Monitoring and Control: With the integration of smart technology, you can remotely monitor and control power distribution through compatible systems. This feature enhances convenience, allows for predictive maintenance, and aids in troubleshooting.

Discover a complete spectrum of advanced Electronics Manufacturing Services tailored to your needs. Our capabilities span from crafting PCBs of 1 to 32 layers, encompassing single-sided, double-sided, and multi-layer configurations, including specialized designs like HDI boards and buried & blind holes boards. Seamlessly managing material procurement, we ensure timely access to top-quality components. Experience rapid prototyping and efficient New Product Introduction (NPI) processes, smoothly transitioning from design to manufacturing.

| ltem | Capability |

|---|---|

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Lead Time | 24 hours expedited service can be offered. 3- 4 days normally for PCBA prototype orders. We will give you an accurate lead time when we quote for you. |

| Size | 50*50mm~510*460mm |

| Board Type | Rigid PCB, Flexible PCB, metal core PCB |

| Min Package | 01005 (0.4mm*0.2mm) |

| Max Package | No limit |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

| Surface Finish | Lead/Lead-free HASL, Immersion gold, OPS, etc. |

| Assembly Types | Surface mount (SMT), Through-hole (DIP), Mixed Technology (SMT & Thru-hole) |

| Component Sourcing | Turnkey (All components sourced by Wenshu), Partial turnkey, Kitted/Consigned |

| BGA Package | BGA Dia. 0.14mm, BGA 0.2mm pitch |

| SMT Parts Presentation | Cut Tape, Partial reel, Reel, Tube, Tray, Laser-cut Stainless Steel |

| Cable Assembly | We supply custom cables, cable assemblies, wiring looms/harnesses and power leads for various industries including automotive, security, mining, medical and entertainment. |

| Stencil | Stencil with or without frame (offered free by Wenshu) |

| Quality Inspection | Visual inspection; AOI checking; BGA placement – X-RAY checking |

| SMT Capacity | 3 Million~4 Million Soldering Pad/day |

| DIP Capacity | 100 Thousand Pins/day |