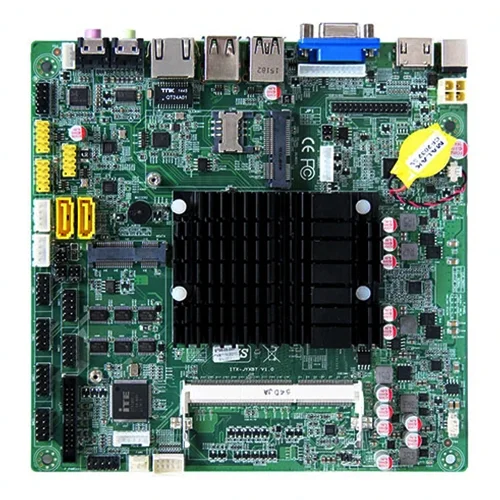

Medical PCB Board Blood Pressure Monitor PCBA

Component manufacturers are continually developing new and smaller packages for components that are mere fractions of a millimeter and have board to component clearances of less than a mil. Pick and place machines have new accessories that allow placement of these almost invisible parts. Components are placed extremely close together.

| Layers | 1-18 Layer |

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Size | 50*50mm~510*460mm |

| Min Package | 01005 (0.4mm*0.2mm) |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

Prototype to Full Turn-Key Assembly

Through-Hole Lead-Free Wave Soldering

Best Price, Genuine Components

Quality Accreditation ISO9001

-

Description

-

Specification

Our Medical PCB Board for Blood Pressure Monitor PCBA is engineered with the utmost precision to meet the exacting standards of medical applications. This PCB board serves as the backbone of blood pressure monitors, facilitating accurate data collection and seamless communication. Designed to elevate patient care, it empowers healthcare professionals with dependable measurements for informed decision-making.

Key Features: Medical PCB Board Blood Pressure Monitor PCBA

- Precision Monitoring: The Medical PCB Board utilizes cutting-edge technology to ensure precise blood pressure measurements. Every detail of its design is meticulously crafted to guarantee accurate data capture.

- Integrated Sensor Interface: The PCB board seamlessly interfaces with advanced blood pressure sensors, enabling real-time data acquisition. This integration ensures that every reading is reliable and consistent.

- Efficient Communication: Equipped with seamless communication capabilities, our PCB board facilitates the transfer of blood pressure data to display units or digital platforms, enabling healthcare providers to monitor patients remotely.

- User-Friendly Design: Designed with both patients and medical professionals in mind, our PCB board offers an intuitive user experience. Its ergonomic design ensures ease of use and patient comfort during blood pressure measurements.

- Quality Manufacturing: Crafted using the highest quality materials and adhering to stringent manufacturing standards, our PCB board guarantees durability and long-term reliability.

- Enhanced Patient Care: By delivering accurate and consistent blood pressure measurements, our PCB board contributes to informed medical decisions, leading to enhanced patient care and improved healthcare outcomes.

Experience the future of medical diagnostics with our Medical PCB Board for Blood Pressure Monitor PCBA. Designed to exceed industry standards, it empowers medical professionals with precise and reliable blood pressure measurements. Witness accurate data capture, seamless communication, and enhanced patient care, all made possible by this technological marvel in medical PCB design.

| ltem | Capability |

|---|---|

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Lead Time | 24 hours expedited service can be offered. 3- 4 days normally for PCBA prototype orders. We will give you an accurate lead time when we quote for you. |

| Size | 50*50mm~510*460mm |

| Board Type | Rigid PCB, Flexible PCB, metal core PCB |

| Min Package | 01005 (0.4mm*0.2mm) |

| Max Package | No limit |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

| Surface Finish | Lead/Lead-free HASL, Immersion gold, OPS, etc. |

| Assembly Types | Surface mount (SMT), Through-hole (DIP), Mixed Technology (SMT & Thru-hole) |

| Component Sourcing | Turnkey (All components sourced by Wenshu), Partial turnkey, Kitted/Consigned |

| BGA Package | BGA Dia. 0.14mm, BGA 0.2mm pitch |

| SMT Parts Presentation | Cut Tape, Partial reel, Reel, Tube, Tray, Laser-cut Stainless Steel |

| Cable Assembly | We supply custom cables, cable assemblies, wiring looms/harnesses and power leads for various industries including automotive, security, mining, medical and entertainment. |

| Stencil | Stencil with or without frame (offered free by Wenshu) |

| Quality Inspection | Visual inspection; AOI checking; BGA placement – X-RAY checking |

| SMT Capacity | 3 Million~4 Million Soldering Pad/day |

| DIP Capacity | 100 Thousand Pins/day |