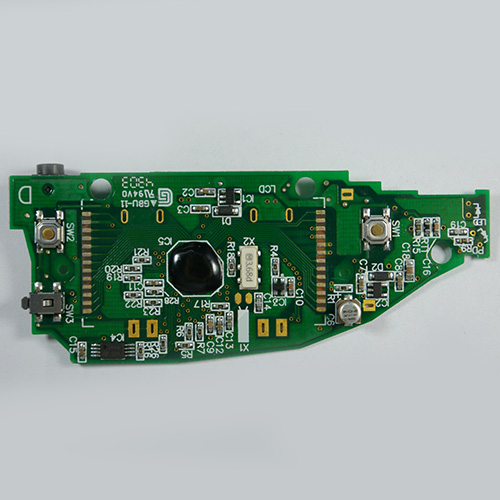

Medical PCB Board Sphygmomanometer PCBA Assembly Supplier

Component manufacturers are continually developing new and smaller packages for components that are mere fractions of a millimeter and have board to component clearances of less than a mil. Pick and place machines have new accessories that allow placement of these almost invisible parts. Components are placed extremely close together.

| Layers | 1-18 Layer |

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Size | 50*50mm~510*460mm |

| Min Package | 01005 (0.4mm*0.2mm) |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

Prototype to Full Turn-Key Assembly

Through-Hole Lead-Free Wave Soldering

Best Price, Genuine Components

Quality Accreditation ISO9001

-

Description

-

Specification

Introducing our cutting-edge Medical PCB Board designed specifically for Sphygmomanometer PCBA Assembly. As a trusted supplier in the medical industry, we deliver precision and reliability to ensure accurate blood pressure measurement. Our advanced PCB technology combined with seamless PCBA assembly results in a vital component that healthcare professionals and patients can depend on.

Key Features:

- Medical-Grade Precision: Our PCB Board is meticulously engineered to meet the stringent demands of medical devices. Expect accurate blood pressure readings with minimal deviation.

- Seamless Integration: Designed for flawless compatibility, our PCB Board seamlessly integrates into Sphygmomanometers, enhancing the overall performance and accuracy of the device.

- Advanced Technology: We employ the latest PCB fabrication techniques, including multi-layer construction and specialized components, to ensure consistent and reliable functionality.

- Rigorous Testing: Each Sphygmomanometer PCB Board undergoes comprehensive testing, including function verification and calibration, to guarantee optimal performance and measurement accuracy.

- Safety Assurance: In the medical field, safety is paramount. Our PCB Board adheres to the highest industry standards, incorporating safety features that protect both patients and healthcare providers.

- Expert Assembly: Our PCBA assembly process is executed by skilled professionals who meticulously handle each component, ensuring precise placement and secure connections for lasting reliability.

Experience our holistic electronics manufacturing solutions, catering to your every need, from PCB fabrication spanning 1 to 32 layers, featuring specialized capabilities such as HDI, buried & blind holes, to seamless material procurement and management. Our expertise extends to rapid PCBA prototyping and NPI services, meticulous through-hole assembly, IC pre-programming, function verification, and rigorous burn-in testing.

Choose our Medical PCB Board for Sphygmomanometer PCBA Assembly, and elevate the accuracy and dependability of your medical device. With a commitment to precision, safety, and innovation, we’re your trusted partner in enhancing healthcare technology

| ltem | Capability |

|---|---|

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Lead Time | 24 hours expedited service can be offered. 3- 4 days normally for PCBA prototype orders. We will give you an accurate lead time when we quote for you. |

| Size | 50*50mm~510*460mm |

| Board Type | Rigid PCB, Flexible PCB, metal core PCB |

| Min Package | 01005 (0.4mm*0.2mm) |

| Max Package | No limit |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

| Surface Finish | Lead/Lead-free HASL, Immersion gold, OPS, etc. |

| Assembly Types | Surface mount (SMT), Through-hole (DIP), Mixed Technology (SMT & Thru-hole) |

| Component Sourcing | Turnkey (All components sourced by Wenshu), Partial turnkey, Kitted/Consigned |

| BGA Package | BGA Dia. 0.14mm, BGA 0.2mm pitch |

| SMT Parts Presentation | Cut Tape, Partial reel, Reel, Tube, Tray, Laser-cut Stainless Steel |

| Cable Assembly | We supply custom cables, cable assemblies, wiring looms/harnesses and power leads for various industries including automotive, security, mining, medical and entertainment. |

| Stencil | Stencil with or without frame (offered free by Wenshu) |

| Quality Inspection | Visual inspection; AOI checking; BGA placement – X-RAY checking |

| SMT Capacity | 3 Million~4 Million Soldering Pad/day |

| DIP Capacity | 100 Thousand Pins/day |