Wenshu SMT PCB Factory–Why You Choose Us

At Wenshu, we stand as a seasoned SMT PCB factory based in China, boasting a rich heritage of 26 years in the industry. Our products have found homes in Europe, America, Japan, Korea, and various other nations.

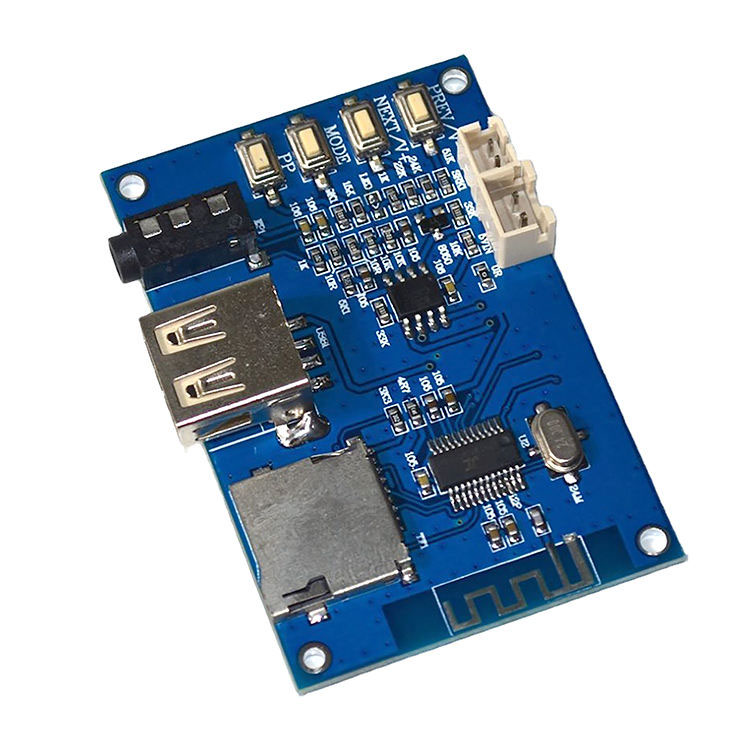

Our comprehensive suite of SMT PCB services encompasses circuit design, PCB layout design, PCB assembly, rigorous testing and inspection, and a host of related PCB offerings. With our one-stop service approach, our esteemed customers can conveniently procure a diverse range of products from us.

Our company proudly houses a cadre of adept technicians who bring substantial expertise to the realm of SMT PCB manufacturing processes. Augmented by advanced equipment and cutting-edge technology, we leave no stone unturned in ensuring that each product we craft stands as a paragon of high quality and unwavering reliability.

Expertise in SMT PCB Manufacturing

As one of China’s most reputable PCB manufacturers, we prioritize quality and customer contentment above all else. Our adept team, comprising experienced engineers and proficient production staff, possesses an intimate understanding of our customers’ unique requirements. We tailor our output to align precisely with customer specifications, enabling us to furnish top-notch products at competitive rates. Since 1997, our company has been dedicated to supplying a diverse array of PCBs to our valued clients.

1. Highlighted Experience and Expertise

Drawing upon more than 26 years of SMT PCB Manufacturing experience, we have honed an exceptionally streamlined and integrated production system. This system empowers us to deliver products of unrivaled quality at the most competitive rates. Our specialization lies in crafting high-mix/low-volume product lines, catering to a diverse clientele spanning industries such as telecommunications, computer peripherals, industrial automation, and medical devices.

Our comprehensive expertise spans every facet of SMT PCB Manufacturing, encompassing High Mix / Low Volume Production, both conventional and automated PCB assembly processes (SMT), custom-printed circuit boards (PCBs), and design for manufacturability (DFM).

2. Meet The Quality Control Rep Who Keeps Our Online Business Awesome

In the realm of manufacturing, quality control takes center stage. It serves as the bedrock of our confidence in product excellence and ensures our customers’ enduring satisfaction.

To uphold these standards, we maintain an in-house quality control representative who vigilantly oversees every facet of our SMT PCB manufacturing process.

Cutting-edge technology and Equipment

1. State-of-the-Art Machinery and Equipment

Wenshu SMT PCB Factory has an LGA, BGA Rework Station, BGA Wire Bonding Station, IC Reflow Oven, SMT Pick and Place Machine Director, and many other advanced equipment to ensure excellent quality SMT production. As a professional manufacturer of SMT PCB, we have very high requirements for all machines.

2. Advanced Technology Galvanizes Best Practices in SMT

Across the entire spectrum of our SMT PCB manufacturing, from the factory floor to the assembly line, our stakeholders reap the advantages of cutting-edge automated equipment. Leveraging this comprehensive suite of equipment and services, we paint a meticulous portrait of quality, enabling more precise and efficient production.

With an automated assembly process, we achieve operational efficiency and cost-effectiveness without compromising on stringent quality benchmarks. This automation liberates manufacturers to concentrate on areas where human expertise enhances product quality, ensuring a harmonious blend of technology and craftsmanship.

Quality Assurance and Certifications

Here’s a closer look at how this role helps us ensure the highest quality products:

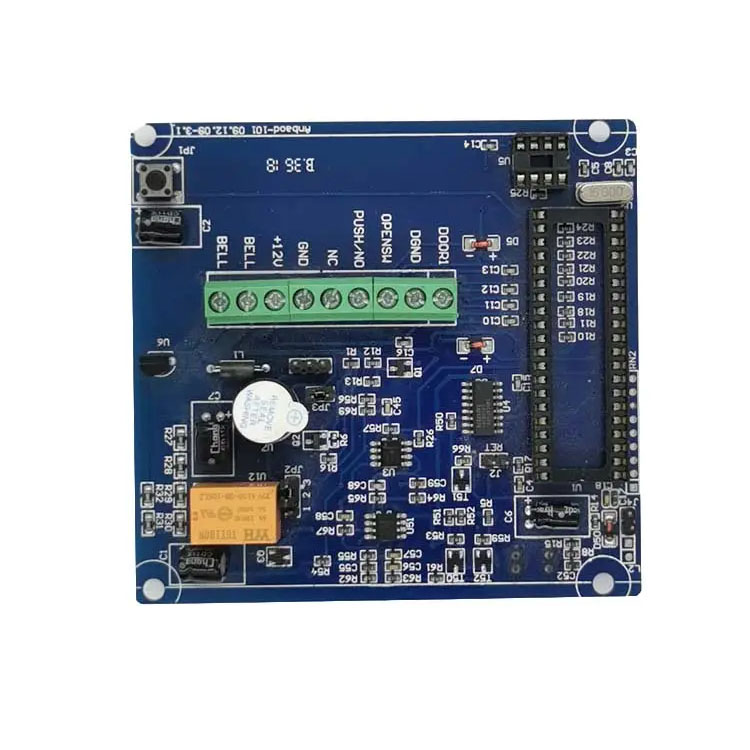

1. Checks Component Performance

Our dedicated Quality Control representative meticulously scrutinizes each component employed in the manufacturing process to guarantee strict adherence to our precise specifications. This comprehensive assessment encompasses a range of components, including resistors, capacitors, diodes, transistors, and more.

2. Measures Solder Paste Thickness & Volume

Every batch of solder paste is measured using a micrometer to ensure proper consistency between batches. The thickness of each paste also must be consistent across all components soldered onto our boards. This ensures that there are no voids or extra solder present on any component soldered onto our boards.

Customization and Flexibility: SMT PCB Factory

How to Handle Complexities: Wenshu

PCB complexity encompasses various facets, including the number of layers within a board, the copper quantity on each layer, the diversity of features, and the component count required for PCB assembly. Several factors contribute to assessing PCB complexity.

One pivotal factor is the nature of the components integrated into the board. For instance, an integrated circuit (IC) chip demands more spatial allocation than a resistor or capacitor. Furthermore, the board’s size plays a significant role, directly influencing its thickness and overall dimensions.

For example, when selecting the board’s dimensions, it’s crucial to consider not only its size but also the intricacy of your design. A sophisticated circuit, such as a field-programmable gate array (FPGA), will occupy more space on a larger board compared to a smaller one. Consequently, opting for a larger board is advisable when dealing with a circuit of above-average complexity.

We Tailor Our Services To Meet Your Unique Needs: Wenshu

We offer a wide range of SMT PCB and assembly services, including:

(1) High-quality PCBs with the best possible price-to-performance ratio; (2) Free design services for your custom-designed products; (3) SMD reflow soldering of all components, including BGAs, BGAs, QFPs, and other surface mount components; (4) Surface mount, and through-hole assembly for any board size or complexity level; (5) In-house testing capability for quality assurance and troubleshooting.

Cost Efficiency: SMT PCB Factory

The key to keeping costs down is using efficient processes and technology. There are several ways that companies can do this:

– Automation:

Automated processes offer cost savings by eradicating labor expenses and enhancing quality consistency. The introduction of automation obviates the necessity for skilled workers to engage in repetitive tasks, thereby reducing labor requirements. This, in turn, affords skilled workers the opportunity to focus on roles that demand their expertise.

As an illustration, automated assembly machines can replace manual labor in SMT PCB factories. This not only trims down the workforce needed but also boosts productivity, as machines operate at a swifter pace compared to human counterparts.

– Productivity:

The more productive our SMT PCB factory is, the more products we can produce in a given period of time and thus earn more revenue from each unit sold at a lower price point than competitors selling similar products at a higher cost per unit. Highly skilled employees who know how to use their equipment correctly and efficiently lead to more productivity by reducing wasted time and materials during production runs.

CONCLUSION

Wenshu PCB is situated in Dongguan City, Guangdong Province, a renowned hub for SMT manufacturing in China. Over the years, we have amassed extensive expertise in PCB manufacturing, earning a stellar reputation globally for our unwavering commitment to stable quality and competitive pricing.

The assembly costs of SMT PCBs are steadily decreasing, which is causing many SMT factories to scale back their workforce. As a result, PCB manufacturers have been forced to either invest in their own SMT machines for in-house assembly or seek OEM services from local SMT facilities. The diminishing profits in this industry reflect the need for both professional expertise and an unwavering dedication to high-quality standards.